Next Gen batteries that can replace lithium-ion batteries: Part 1

Lithium-ion batteries are the most widely used type of rechargeable batteries in the world. They power everything from smartphones and laptops to electric vehicles and grid storage. However, lithium-ion batteries have some limitations, such as low energy density, high cost, safety issues, and environmental impact. Therefore, researchers and innovators are constantly looking for alternative battery technologies that can offer better performance, lower cost, higher safety, and less environmental impact. In this blog, we will explore some of the next generation batteries that can potentially replace lithium-ion batteries in the future.

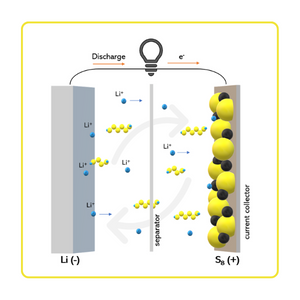

Lithium-Sulfur batteries

Lithium-Sulfur batteries are a type of rechargeable batteries that use lithium metal as the anode and sulfur as the cathode. Lithium-sulfur batteries have several advantages over lithium-ion batteries, such as:

Higher Energy Density: Lithium-sulfur batteries can store up to 10 times more energy per unit mass than lithium-ion batteries, which means they can provide longer runtimes and lighter weights for the same applications.

Lower Cost: Lithium-sulfur batteries use abundant and cheap materials, such as sulfur and carbon, which can reduce the cost of battery production and recycling.

Higher Safety: Lithium-sulfur batteries do not contain flammable liquid electrolytes or toxic metals, such as cobalt and nickel, which can reduce the risk of fire and explosion.

Challenges with Lithium-Sulfur

Low Cycle Life: Lithium-sulfur batteries tend to degrade quickly after repeated charging and discharging cycles, due to the formation of polysulfides that dissolve in the electrolyte and cause capacity loss.

Low Power Density: Lithium-sulfur batteries have low electrical conductivity and high internal resistance, which limit their ability to deliver high power output for fast charging or high-performance applications.

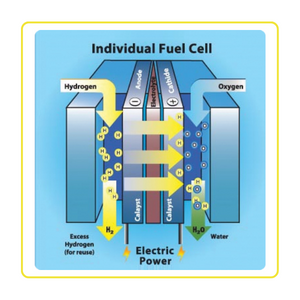

Hydrogen fuel cells

Hydrogen fuel cells are a type of electrochemical device that converts chemical energy from hydrogen and oxygen into electrical energy and water. Hydrogen fuel cells have several advantages over lithium-ion batteries, such as:

High Energy Density: Hydrogen fuel cells can store more energy per unit mass than lithium-ion batteries, which means they can provide longer runtimes and longer driving ranges for electric vehicles.

Zero Emissions: Hydrogen fuel cells only produce water as a by-product, which means they do not emit any greenhouse gases or pollutants that contribute to climate change or air quality problems.

Fast Refuelling: Hydrogen fuel cells can be refuelled in minutes, similar to gasoline or diesel vehicles, which means they do not require long charging times or extensive charging infrastructure.

Challenges with Hydrogen Fuel Cell

High Cost: Hydrogen fuel cells are expensive to produce and maintain, due to the use of rare and costly materials, such as platinum and membranes, and the need for complex and reliable systems.

Low Availability: Hydrogen fuel cells require a steady supply of pure hydrogen gas, which is not widely available or affordable in most places and requires energy-intensive and carbon-intensive processes to produce from fossil fuels or renewable sources.

Low Efficiency: Hydrogen fuel cells lose a lot of energy during the conversion from hydrogen to electricity, due to the losses in the electrolysis, compression, transportation, storage, and fuel cell stages.

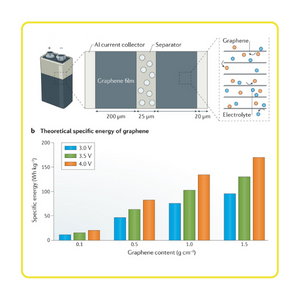

Graphene supercapacitor batteries

Graphene supercapacitor batteries are a type of hybrid device that combine the features of supercapacitors and batteries. Super capacitors are a type of energy storage devices that can charge and discharge very quickly, but have low energy density. Batteries are a type of energy storage devices that can store a lot of energy, but have slow charging and discharging rates. Graphene supercapacitor batteries use graphene, a one-atom-thick layer of carbon atoms, as the electrode material, which can enhance both the power and energy density of the device. Graphene supercapacitor batteries have several advantages over lithium ion batteries, such as:

High Power Density: Graphene supercapacitor batteries can deliver high power output for fast charging or high-performance applications, such as electric vehicles or portable electronics.

Long Cycle Life: Graphene supercapacitor batteries do not suffer from capacity degradation or memory effect, which means they can last for thousands of charging and discharging cycles without losing performance.

Flexible and Lightweight: Graphene supercapacitor batteries can be made into thin and flexible sheets or films, which can reduce the weight and size of the device and enable novel applications, such as wearable or foldable electronics.

Challenges with graphene supercapacitor batteries

Low Energy Density: Graphene supercapacitor batteries still have lower energy density than lithium ion batteries, which means they cannot store as much energy for the same volume or mass.

High Cost: Graphene supercapacitor batteries are expensive to produce and scale up, due to the challenges in synthesizing high-quality and large-scale graphene and assembling the device components.

Thermal Stability: Graphene supercapacitor batteries may suffer from thermal runaway or overheating, due to the high current density and low thermal conductivity of graphene.

Redox Flow Batteries

Redox flow batteries are a type of rechargeable batteries that use liquid electrolytes stored in external tanks as the active materials. Redox flow batteries have several advantages over lithium ion batteries, such as:

Scalable and Modular: Redox flow batteries can easily adjust their power and energy capacity by changing the size and number of the tanks and cells, which means they can meet various application requirements and optimize the cost-performance ratio.

Long Lifespan: Redox flow batteries have low degradation and self-discharge rates, which means they can operate for long periods of time without losing performance or requiring maintenance.

High Safety: Redox flow batteries do not contain flammable or explosive materials, which means they do not pose fire or explosion hazards.

Challenges with Redox Flow Batteries

Low energy density: Redox flow batteries have low energy density compared to lithium ion batteries, which means they require large and heavy tanks and pumps to store and circulate the electrolytes.

Low Efficiency: Redox flow batteries lose a lot of energy during the charging and discharging processes, due to the losses in the electrolyte transport, membrane crossover, and shunt currents.

Chemical Stability: Redox flow batteries may suffer from chemical degradation or contamination of the electrolytes, which can affect the performance and lifespan of the device.

Aluminium Graphite Batteries

Aluminium graphite batteries are a type of rechargeable batteries that use aluminium metal as the anode and graphite as the cathode. Aluminium graphite batteries have several advantages over lithium ion batteries, such as:

High Capacity: Aluminium graphite batteries can store more charge per unit mass than lithium ion batteries, due to the high theoretical capacity of aluminium metal.

Low Cost: Aluminium graphite batteries use cheap and abundant materials, such as aluminium and graphite, which can reduce the cost of battery production and recycling.

Eco-Friendly: Aluminium graphite batteries do not contain toxic or hazardous materials, such as cobalt or lithium, which can reduce the environmental impact of battery disposal.

Challenges with Aluminium Graphite Batteries

Low Voltage: Aluminium graphite batteries have low operating voltage compared to lithium ion batteries, which means they require more cells in series to achieve the same output voltage.

High Self-Discharge: Aluminium graphite batteries have high self-discharge rate compared to lithium ion batteries, which means they lose a lot of charge when not in use.

Poor Cyclability: Aluminium graphite batteries tend to form dendrites or whiskers on the aluminium anode during repeated charging and discharging cycles, which can cause short circuits or capacity loss.