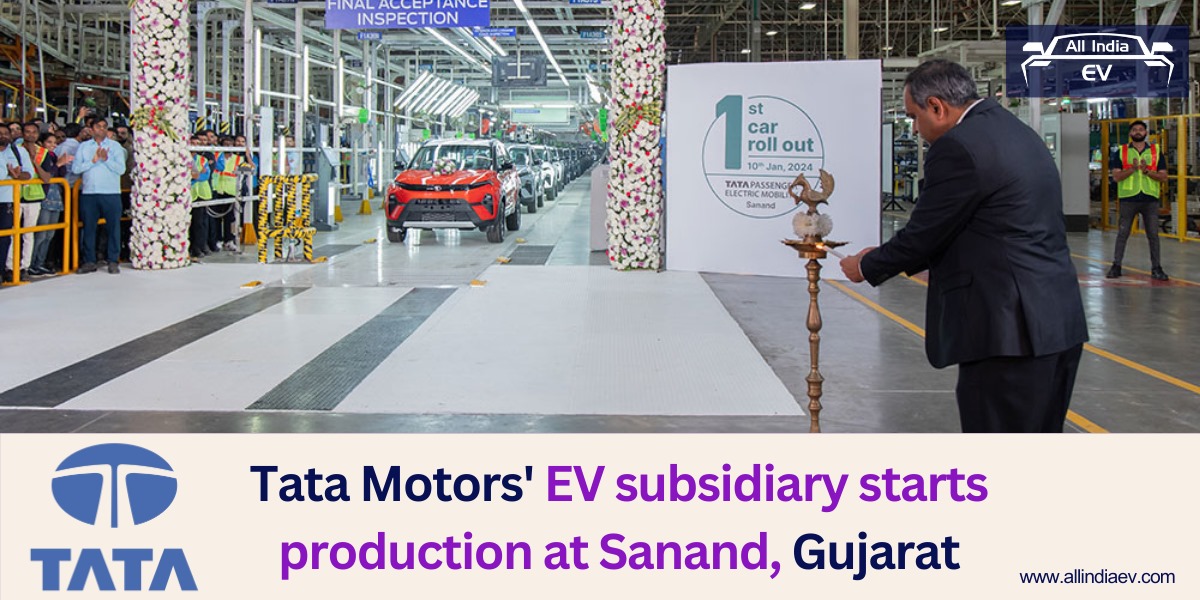

Tata Passenger Electric Mobility Begins Manufacturing at New Sanand Facility in Gujarat

Tata Passenger Electric Mobility Ltd. (TPEM) has started making passenger vehicles at its new factory in Sanand, Gujarat. This is a big step for the company. The first Tata car from this top-notch factory was made in a special event attended by TPEM’s Managing Director, Shailesh Chandra, and leaders from the Passenger and Electric Vehicles divisions.

“Witnessing the first car roll out of the new TPEM facility in Sanand is a proud moment for us. We have successfully retooled the factory in the shortest span of 12 months, taking it to a new level to accommodate a wide range of existing products and future new models. I extend my heartfelt gratitude to the Government of Gujarat for its wholesome support and our employees without whom this accomplishment would not have been possible. I am confident that this facility will play a pivotal role in steering Tata Motors, especially TPEM, towards achieving newer feats.”

Shailesh Chandra, Managing Director, Tata Motors Passenger Vehicles Limited & Tata Passenger Electric Mobility Limited said.

“Tata Motors Passenger & Electric Vehicles business has delivered market-beating growth over the last few years. We have strong plans to sustain this momentum, with our robust pipeline of future-ready “New Forever” products and proactive investments in electric vehicles. With existing capacities near saturation, this new facility will unlock an additional state-of-the-art manufacturing capacity of 300,000 units per annum which is scalable to 420,000 units per annum.”

He further added.

This new facility was purchased from Ford India on January 10, 2023. It is located in the industrial hub of GIDC Sanand and has access to a robust network of suppliers. Covering 460 acres, it will be Tata Motors’ second plant in Gujarat to manufacture ICE and EV models. The plant has four main shops: Stamping, Body construction, Paint, and Final Assembly Shop. All shops are highly automated and equipped with the newest technology to ensure precision manufacturing. The facility has implemented several world-class technologies that will set a new benchmark within the industry.

Tata Motors has invested in upskilling its workforce by providing them with a Diploma, Bachelor of Engineering, and Master’s Degree, as applicable. In line with Tata Motors’ commitment to sustainability, a 50 KW solar rooftop is installed in the plant, which today employs over 1000 people (including staff and technicians) and will create 1000 additional jobs in the region in the next three to four months, in line with the production ramp-up plans.

✅ Press shop: new dies for stamping vital skin panels;

✅ Weld shop: additional robots have been added to all lines; new grippers and fixtures have been added;

✅ Paint shop: handling system modifications; external robot programming; internal robotic painting and waxing setup;

✅ Assembly shop: handling system modifications and end-of-line system.

Tata Motors has invested in upskilling its workforce by providing them with a Diploma, Bachelor of Engineering, and Master’s Degree, as applicable. In line with Tata Motors’ commitment to sustainability, a 50 KW solar rooftop is installed in the plant, which today employs over 1000 people (including staff and technicians) and will create 1000 additional jobs in the region in the next three to four months, in line with the production ramp-up plans.