EV Motors: Types, Working Principles, and Selection Criteria

Electric vehicles (EVs) are gaining popularity as they provide environmental benefits, lower operating costs, and better performance than conventional vehicles. The electric motor is the heart of an EV, as it transforms electrical energy into mechanical energy to move the wheels. Various types of electric motors can be used in EVs, each with its pros and cons. In this article, we will explore the main types of EV motors, how they work, and how to choose the best motor for a specific EV application.

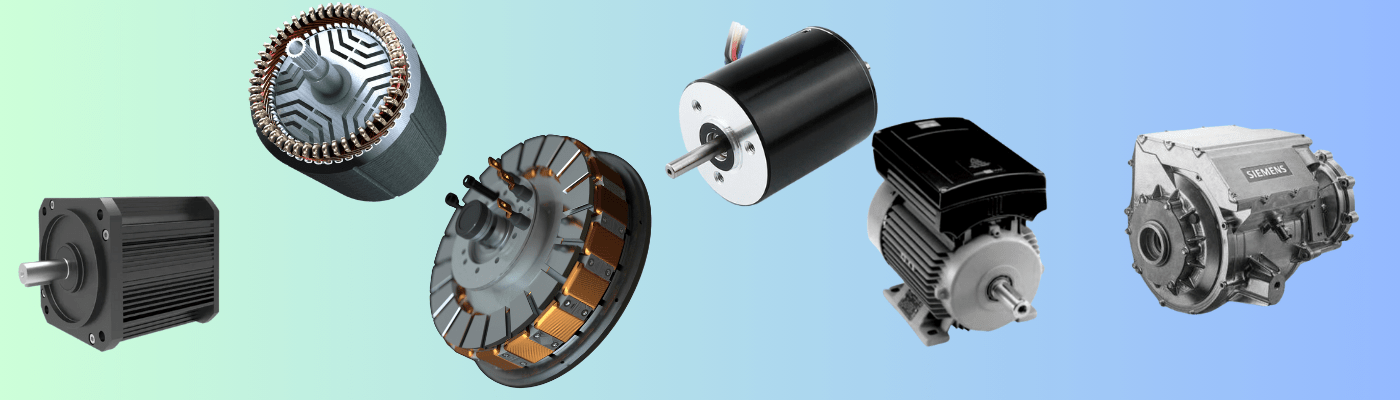

EV Motors: A Brief Overview Electric motors can be broadly categorized into two groups: direct current (DC) motors and alternating current (AC) motors. DC motors run on a constant voltage and current source, while AC motors run on a varying voltage and current source. Both groups of motors can be further classified into subtypes based on their structure, operation, and control methods. Some of the common types of EV motors are:

DC Motors: DC motors are simple and sturdy in design, making them suitable for EV applications. They have high starting torque and good efficiency, making them ideal for low-speed applications such as electric bikes and scooters.

AC Induction Motors: AC induction motors are more complicated than DC motors but have higher efficiency and power density. They are suitable for high-speed applications such as electric cars and buses.

Types of EV Motors

Permanent Magnet Synchronous Motors (PMSM): A Permanent Magnet Synchronous Motor (PMSM) is a kind of AC synchronous motor that uses permanent magnets to generate a steady magnetic field in the rotor.

Brushless DC Motors (BLDC): BLDC motors are the most preferred motors for EV applications due to their traction characteristics. They have high efficiency, low maintenance, and high power density, making them ideal for electric cars and bikes.

Axial Flux Motors: Axial flux motors are a type of PMSM motor that has a unique design with the rotor and stator arranged in a disc-like shape. They have high power density, efficiency, and torque density, making them ideal for high-performance EVs.

Interior Permanent Magnet Motor (IPMM): The IPM motor stands for Interior Permanent Magnet motor, which is a type of permanent magnet synchronous motor (PMSM). The permanent magnets are embedded inside the rotor, which is different from the brushless DC motor where the permanent magnets are on the stator.

Switched Reluctance Motors: Switched reluctance motors are simple in design and have high efficiency and power density. They are suitable for low-speed applications such as electric bikes and scooters.

Integrated Motor-Drive Systems: Integrated motor-drive systems combine the motor and drive electronics into a single unit, reducing weight and cost. They are suitable for a wide range of EV applications.

Working Principles of EV Motors

The working principle of an electric motor is based on the interaction between the electric current and the magnetic field. When a current-carrying conductor is placed in a magnetic field, it experiences a force that is perpendicular to both the current and the field. This force is called the Lorentz force, and it can be used to generate torque and rotation. The direction of the force can be determined by the right-hand rule: if the thumb points in the direction of the current, and the index finger points in the direction of the field, then the middle finger points in the direction of the force.

The working principle of a DC motor is based on the commutation of the current in the armature winding. The armature winding is a coil of wire that rotates in a fixed magnetic field created by the field winding or permanent magnets. The commutation is the process of reversing the direction of the current in the armature winding at the appropriate time so that the torque is always in the same direction. The commutation can be done mechanically by using brushes and commutators, or electronically by using an electronic controller.

The working principle of an AC motor is based on the synchronization of the rotating magnetic field and the rotor. The rotating magnetic field is created by the stator winding, which is a set of coils that are connected to an AC power source. The rotor is the part of the motor that rotates and follows the magnetic field. The rotor can be either an induction rotor, which has no magnets or windings, or a synchronous rotor, which has permanent magnets or windings. The speed of the rotor depends on the frequency of the AC power source and the number of poles in the stator and rotor.

Selection Criteria for EV Motors

The selection of the best EV motor depends on several factors, such as the performance requirements, the cost, the size, the weight, the efficiency, the reliability, the maintenance, and the environmental impact. Some of the criteria for choosing the best EV motor are:

Performance: The performance of an EV motor is measured by its torque, speed, and power. Torque is the rotational force that the motor produces, speed is the rate of rotation of the motor, and power is the product of torque and speed. The performance of an EV motor should match the performance of the vehicle, such as the acceleration, the top speed, and the hill climbing ability.

Cost: The cost of an EV motor includes the initial cost, the operating cost, and the maintenance cost. The initial cost is the price of the motor and its components, such as the controller, the inverter, the battery, and the charger. The operating cost is the cost of the electricity used by the motor and its components. The maintenance cost is the cost of the repairs and replacements of the motor and its components. The cost of an EV motor should be affordable and competitive with the cost of a conventional vehicle.

Size and Weight: The size and weight of an EV motor affect the space and the load of the vehicle. The size and weight of an EV motor should be as small and light as possible, without compromising performance and efficiency.

Efficiency: The efficiency of an EV motor is the ratio of the output power to the input power. The efficiency of an EV motor should be as high as possible, as it reduces energy losses and the operating cost.

Reliability: The reliability of an EV motor is the ability of the motor to operate without failures or breakdowns. The reliability of an EV motor should be as high as possible, as it reduces maintenance costs and downtime.

Maintenance: The maintenance of an EV motor is the frequency and complexity of the repairs and replacements of the motor and its components. The maintenance of an EV motor should be as low as possible, as it reduces the maintenance cost and downtime.

Environmental Impact: The environmental impact of an EV motor is the amount of greenhouse gas emissions and other pollutants that the motor and its components produce. The environmental impact of an EV motor should be as low as possible, as it reduces global warming and air pollution.

The selection of the most suitable motor for an EV application depends on various factors, such as the performance, cost, reliability, and environmental impact of the motor.

Some of the main criteria for selecting an EV motor are:

Torque: This is the measure of the rotational force that the motor can produce. It is expressed in Newton-meters (Nm) or pound-feet (lb-ft). The torque determines the acceleration, hill climbing, and towing capacity of the EV. The torque requirement depends on the weight, size, and speed of the EV. Generally, a higher torque is desirable for an EV motor, as it can improve the performance and efficiency of the EV.

Speed: This is the measure of the rotational speed that the motor can achieve. It is expressed in revolutions per minute (RPM) or radians per second (rad/s). The speed determines the maximum velocity and range of the EV. The speed requirement depends on the transmission, gear ratio, and wheel size of the EV. Generally, a higher speed is desirable for an EV motor, as it can reduce the size and weight of the motor and the drivetrain.

Efficiency: This is the measure of the ratio of the output mechanical power to the input electrical power of the motor. It is expressed as a percentage (%) or a decimal (0-1). The efficiency determines the energy consumption and battery life of the EV. The efficiency requirement depends on the driving cycle, climate, and charging infrastructure of the EV. Generally, a higher efficiency is desirable for an EV motor, as it can reduce the operating cost and greenhouse gas emissions of the EV.

Power Density: This is the measure of the ratio of the output mechanical power to the volume or mass of the motor. It is expressed in watts per cubic meter (W/m3) or watts per kilogram (W/kg). The power density determines the size and weight of the motor and the EV. The power density requirement depends on the design, packaging, and performance of the EV. Generally, a higher power density is desirable for an EV motor, as it can increase the space and payload of the EV.

The selection of the right motor for an EV also involves determining the motor drive mechanism, motor parameters and specifications, and motor performance.

Load dimensions and mass: These are the physical parameters of the load that the EV motor has to move or support, such as the vehicle body, wheels, passengers, etc. They affect the torque and power requirements of the motor, as well as the efficiency and performance of the EV.

Each part’s dimension and mass: These are the physical parameters of each component of the EV motor, such as the rotor, stator, bearings, shaft, etc. They affect the weight, size, and inertia of the motor, as well as the cooling and ventilation requirements.

Coefficient of friction of each moving part sliding surface: This is a measure of how much resistance there is between two surfaces that are in contact and moving relative to each other, such as the bearings and the shaft, or the brushes and the commutator. It affects the frictional losses, heat generation, and wear and tear of the motor parts.

Operating time and speed: These are the temporal parameters of the EV motor operation, such as how long and how fast it has to run. They affect the duty cycle, thermal loading, and fatigue of the motor, as well as the battery life and range of the EV.

Positioning distance and time: These are the spatial and temporal parameters of the EV motor control, such as how far and how fast it has to move to a desired position. They affect the accuracy, precision, and responsiveness of the motor, as well as the feedback and sensing mechanisms.

Resolution: This is a measure of how finely the EV motor can adjust its position, speed, or torque. It depends on the number of steps, poles, or phases of the motor, as well as the resolution of the encoder, sensor, or controller. It affects the smoothness, stability, and noise of the motor operation.

Stopping accuracy: This is a measure of how closely the EV motor can stop at a desired position, speed, or torque. It depends on the braking, damping, and feedback mechanisms of the motor, as well as the inertia and friction of the load and the motor parts. It affects the safety, reliability, and efficiency of the motor operation.

Voltage and power supply: These are the electrical parameters of the EV motor input, such as the voltage level, current rating, frequency, and waveform of the power source. They affect the compatibility, efficiency, and performance of the motor, as well as the design and selection of the motor driver, converter, or inverter.

Position holding: This is the ability of the EV motor to maintain a constant position, speed, or torque when there is no external force or disturbance. It depends on the type, mode, and feedback of the motor control, as well as the stiffness and damping of the motor and the load. It affects the stability, accuracy, and energy consumption of the motor operation.

Environment of operation: This is the external condition that the EV motor has to operate in, such as temperature, humidity, pressure, dust, vibration, etc. It affects the durability, reliability, and safety of the motor, as well as the protection and insulation requirements.

IP rating: This is a standard that defines the degree of protection that the EV motor enclosure provides against ingress of solid objects, dust, water, and accidental contact. It consists of two digits, where the first digit indicates the protection against solids and the second digit indicates the protection against liquids. It affects the suitability, maintenance, and lifespan of the motor for different environments.

Electric motors are the key components of EVs, as they provide the power and the motion for the vehicles. Various types of electric motors can be used in EVs, each with its advantages and disadvantages.

The main types of EV motors are DC motors, AC induction motors, PMSM motors, BLDC motors, axial flux motors, switched reluctance motors, and integrated motor-drive systems.

The working principle of an electric motor is based on the interaction between the electric current and the magnetic field, which generates torque and rotation. The selection of the best EV motor depends on several factors, such as performance, cost, size, weight, efficiency, reliability, maintenance, and environmental impact. By choosing the best EV motor, one can enjoy the benefits of EVs, such as the environmental benefits, the lower operating costs, and the better performance.

Some Research Papers for your reference

Review and Development of Electric Motor Systems and Electric Powertrains for New Energy Vehicles: This paper presents a comprehensive review of the recent research and technical progress of electric motor systems and electric powertrains for new energy vehicles. It compares different types of electric motors, such as direct current motor, induction motor, and synchronous motor, and evaluates their performance, efficiency, and reliability. It also discusses different control strategies, converters, and hybrid powertrains for EV applications. Finally, it proposes a technology roadmap for the next 15 years regarding traction motor, power electronic converter and electric powertrain as well as the key materials and components at each time frame.

Electrical Motors for Electric Vehicle – A Comparative Study: This paper compares the most popular classes of electric motors being used for EV applications, such as induction motor, permanent magnet motor, and switched reluctance motor. It analyzes their efficiency, power density, reliability, and size, and suggests the best suitable motor type depending on the power requirement.

A survey on comparison of electric motor types and drives used for electric vehicles: This paper surveys the electric motor types and drives used for EV applications, such as induction motor, permanent magnet motor, switched reluctance motor, and brushless DC motor. It compares their efficiency, cost, weight, cooling, maximum speed, reliability, fault tolerance, power ratings, and vehicle acceleration time.