EV Skateboard Explain: Types, Features and Manufactures

Electric vehicles (EV) are shaking up the automotive industry, and one of the most significant changes is happening underneath the hood. The traditional car platform, designed around a combustion engine, is undergoing a radical transformation to accommodate the unique requirements of electric powertrains.

Unlike conventional cars, EVs don’t need a large engine compartment to house a bulky engine and gearbox. This opens up new possibilities for vehicle design and layout. Instead of the familiar front-engine, mid-cabin, rear-cargo arrangement, EV manufacturers are experimenting with various configurations. Some are pushing the battery pack to the floor, creating a flat, spacious interior. Others are placing the motor in the wheels for even more efficient power delivery.

The flexibility offered by EV platforms allows for innovative designs, such as smaller, more maneuverable city cars and larger, more luxurious vehicles with extended range. As battery technology continues to advance, we can expect to see even more exciting and diverse EV platforms emerging in the years to come.

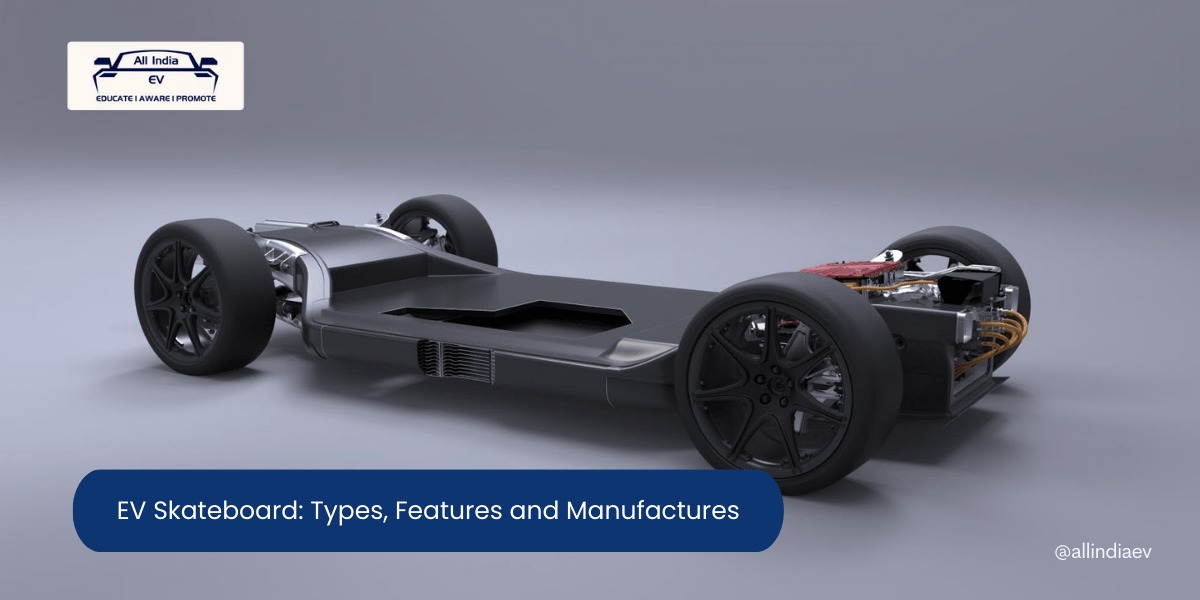

EV Skateboard Chassis: A Foundation for Electric Vehicles

An electric skateboard chassis serves as the foundation for a battery electric vehicle’s platform. This base structure houses the batteries, electric motors, and other critical electronic components, providing the necessary power and control for the vehicle’s operation.

Skateboard chassis offer versatility and efficiency, enabling the development of a wide range of electric vehicles. While the initial investment in developing a skateboard chassis can be substantial, the long-term benefits, such as reduced material costs and increased amortization over a larger production volume, make it a worthwhile investment.

Safety and reliability are paramount in any EV skateboard platform. These factors play a crucial role in a car manufacturer’s marketing strategy. Developing a successful skateboard platform requires advanced engineering expertise and significant investment. However, this approach can be attractive to new manufacturers who want to enter the EV market without the need to develop their own platforms from scratch.

The era of EVs presents new opportunities for car manufacturers. By purchasing EV skateboard platforms from specialized suppliers, manufacturers can focus on assembling vehicles and differentiating their products through unique features and branding. This approach is similar to the distribution model, where companies sell products without manufacturing them themselves.

EV Skateboard Platforms: Driving Innovation in Electric Vehicles

Developing EV skateboard platforms requires a meticulous focus on reliability and safety. Manufacturers must implement stringent quality control measures to ensure the platform’s integrity and performance.

Adaptability is another key factor in the success of EV skateboard platforms. The automotive industry is evolving rapidly, and manufacturers must be able to adjust their platforms to meet changing market demands and technological advancements.

Global automotive giants such as Tesla, Rivian, Volkswagen, Byton, and Faraday are already leveraging EV skateboard platforms to power their electric vehicles. In India, Hyundai, Mahindra EV, and Toyota are also exploring this technology to introduce innovative electric vehicles with features like reduced weight, fast charging, and powerful performance.

The adoption of EV skateboard platforms signifies a significant shift in the automotive industry. These platforms offer a versatile and efficient foundation for developing a wide range of electric vehicles, driving innovation and accelerating the transition to sustainable transportation.

Electric vehicles (EVs) can be built on various chassis types, each with its own unique characteristics and advantages. Here’s a breakdown of the most common types:

Monocoque Chassis

- Description: The most common type, a monocoque chassis combines the car’s structure, foundation, and body into a single unit.

- Advantages: Lightweight, compact, and easy to manufacture.

- Disadvantages: Can be less durable in severe impacts.

Ladder Frame Chassis

- Description: A traditional frame with two long, parallel beams connected by shorter crossmembers.

- Advantages: Durable, off-road capable, and easy to repair.

- Disadvantages: Heavy, less aerodynamic, and can limit interior space.

Backbone Chassis

- Description: A strong tubular backbone connects the front and rear suspension attachment points.

- Advantages: Stiff, durable, and can handle significant loads.

- Disadvantages: Expensive to produce, can be heavy, and may limit design flexibility.

Space Frame Chassis

- Description: A skeletal structure of tubes with triangulated connections, often used in racing cars.

- Advantages: Extremely lightweight, highly customizable, and can be very strong.

- Disadvantages: Complex to design and manufacture, can be expensive.

The choice of chassis type depends on factors such as the intended use of the EV, desired performance characteristics, and cost considerations. For example, a monocoque chassis is well-suited for passenger cars due to its lightweight and compact design, while a ladder frame chassis might be preferred for off-road vehicles or commercial trucks.

The Electric Skateboard Revolution: A Platform for Innovation

The electric skateboard, a versatile chassis that can be adapted to various vehicle types, is rapidly gaining traction in the automotive industry. This innovative platform offers a host of benefits, including streamlined development, simplified assembly, and increased efficiency.

At the core of the electric skateboard is a modular design, allowing manufacturers to easily scale up or down the platform to suit different vehicle needs. From compact city cars to heavy-duty commercial trucks, the skateboard can accommodate a wide range of applications.

The electric skateboard also provides a valuable tool for standardizing and simplifying the development process. By sharing common components and systems across different vehicle models, manufacturers can reduce costs, improve quality, and accelerate time-to-market.

Several major automakers have already embraced the electric skateboard platform. Tesla, known for its pioneering work in electric vehicles, is using the skateboard to underpin its Model S and Model X. Other companies, such as Foxconn, Hyundai, and REE Automotive, are also investing heavily in this technology. Even traditional automakers like General Motors and Toyota are exploring the potential of the electric skateboard to help them transition to a more sustainable future.

As the electric skateboard continues to evolve, it is poised to become a cornerstone of the automotive industry. Its versatility, efficiency, and scalability offer a promising path toward a cleaner, more sustainable transportation future.

The Electric Skateboard: A Foundation for the Future

The electric skateboard, the underlying platform for many modern electric vehicles, must meet a rigorous set of requirements to ensure safety, performance, and longevity. A robust and lightweight chassis is essential for protecting occupants in a collision, handling torsional vibrations from driving conditions, and accommodating the weight of the battery pack throughout its lifespan.

As the demand for automobiles continues to grow, particularly in developing nations, the electric skateboard offers a promising solution. By reducing production costs and improving efficiency, this platform can make electric vehicles more accessible to a wider range of consumers. In the future, the electric skateboard could enable a significant increase in car production, meeting the growing global demand for sustainable transportation.

To stay ahead in the electric vehicle era, manufacturers must embrace innovation and challenge conventional thinking. By disrupting the status quo and exploring new approaches to design and production, companies can position themselves as leaders in this rapidly evolving market. The electric skateboard, with its potential for versatility, efficiency, and affordability, offers a compelling foundation for the future of automotive transportation.