PLI payouts, Battery Pack Aadhaar, and electronics localisation are converging into a new enforcement layer.

For years, India’s EV story was primarily an adoption story: registrations, launches, subsidies, market share.

That phase isn’t over, but the centre of gravity is shifting. A new layer is being built underneath the EV ecosystem and it’s less glamorous, more powerful: traceability + localisation enforcement + electronics capability.

In the last week alone, three developments point to the same direction:

- PLI Auto incentives disbursed at meaningful scale,

- a proposed Battery Pack Aadhaar digital identity framework,

- and expanded push to localise electronics components including Li-ion cell ecosystem parts and power electronics.

This is how systems mature: first you chase growth, then you build the plumbing that prevents the ecosystem from becoming a warranty-and-safety mess.

What happened (facts-only)

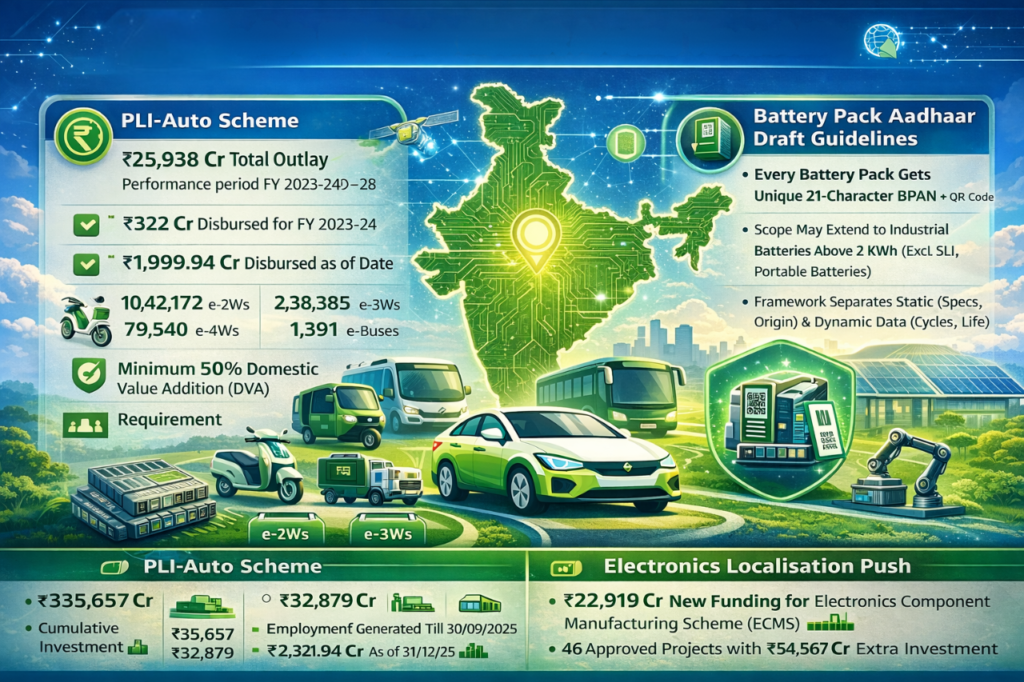

- Under the PLI-Auto scheme, government disclosed:

- total outlay ₹25,938 crore, performance period FY 2023–24 to FY 2027–28,

- ₹322 crore disbursed in FY 2024–25 for performance year FY 2023–24,

- ₹1,999.94 crore disbursed for performance year 2024–25 (as of date in the disclosure),

- incentives linked to 10,42,172 e-2W, 2,38,385 e-3W, 79,540 e-4W, and 1,391 e-buses,

- minimum 50% Domestic Value Addition (DVA) requirement,

- cumulative investment ₹35,657 crore, cumulative determined sales ₹32,879 crore, and employment 48,974 generated (till 30/09/2025), with cumulative incentives disbursed ₹2,321.94 crore as on 31/12/2025.

- The Centre floated draft guidelines for a Battery Pack Aadhaar system:

- every battery pack used in EVs and large industrial applications gets a 21-character BPAN plus QR code,

- scope may extend to industrial batteries above 2 kWh, excluding SLI and portable batteries (as reported),

- the framework separates static data (manufacturer, specs, composition, carbon footprint) and dynamic data (SoH, cycles, thermal events, end-of-life status) hosted on a central server,

- stated intent includes curbing counterfeits, improving safety monitoring, and supporting recycling efficiency,

- it also links to verifying domestic origin for schemes like ACC PLI (as described).

- Electronics localisation push expanded under the Electronics Component Manufacturing Scheme (ECMS):

- scheme funding ₹22,919 crore approved March 28, 2025,

- 46 applications approved with investment intention ₹54,567 crore,

- approvals span 22 projects across eight states (as reported),

- MeitY approved 17 additional proposals in mid-November with ₹7,172 crore investment and projected production ₹65,111 crore (as reported),

- stated goal: scale manufacturing value toward $500 billion by 2030–31.

India is moving from “EV adoption” to “EV enforceability”.

That enforceability comes from three levers:

- Money with conditions (PLI + DVA)

- Identity with lifecycle visibility (Battery Aadhaar)

- Component capability (electronics + power electronics + cell ecosystem parts)

When these three align, you can finally run a serious EV market where safety, warranty, and localisation claims don’t rely on marketing PDFs.

Why this matters (3 angles)

1) Market/strategy implication

PLI payouts are not just incentives. They are signals of what the government is willing to reward: scale tied to localisation thresholds. Once capital sees predictable disbursement and clear compliance criteria, it becomes easier to finance factories, supplier tooling, and long-term capacity. But there’s a second effect: companies that can’t meet DVA consistently will get structurally squeezed, not just “outcompeted”.

2) Technical implication

Battery Pack Aadhaar is basically the beginning of a battery accountability system. If implemented seriously, it changes how the ecosystem handles:

- counterfeit packs,

- thermal incidents and root-cause analysis,

- warranty and recall workflows,

- end-of-life routing and recycling compliance,

- and even financing (because traceable assets are easier to underwrite).

The detail about static vs dynamic data is crucial: it implies the system wants to track real operating behaviour, not just a label on the pack.

3) Policy/capital implication

Electronics localisation is the quiet backbone here. EVs are becoming electronics products on wheels. Localising PCBs, connectors, modules, and parts of the Li-ion ecosystem reduces import dependencies and can lower lead-time risk. It also makes enforcement easier: you can’t run traceability frameworks without the digital and component infrastructure to support them.

In short: the next phase of India’s EV market will reward companies that can prove what they built, where they built it, and how it behaved in the field.

What’s “Not disclosed” (and why it matters)

- Battery Aadhaar implementation details: platform operator, compliance timelines, penalties for non-compliance. Without this, it risks becoming a “QR sticker initiative” rather than a governance system.

- Data access governance: who can read dynamic data, under what consent model, and how disputes are resolved. Without this, trust collapses.

- Cost of compliance: OEMs, pack makers, recyclers will need systems integration. If cost burden isn’t mapped, adoption will be slow or superficial.

Execution Risk Ledger

- Data integrity risk: if inputs are unreliable or gamed, the system becomes theatre.

- Privacy and access friction: unclear rules on who can access dynamic battery data can trigger pushback from OEMs and consumers.

- Integration burden: BMS compatibility, server architecture, and field connectivity are not trivial at India scale.

- Fragmentation risk: if each programme builds separate databases, interoperability dies and compliance becomes expensive.

- Enforcement gap: without penalties and audit capacity, “traceability” becomes optional in practice.

Who wins / who gets squeezed

Who wins

- OEMs and battery players who can consistently meet DVA and prove provenance.

- Recyclers and service networks that can plug into lifecycle tracking and demonstrate compliance.

Who gets squeezed

- Grey-market suppliers and counterfeit channels.

- Players depending on loosely documented imports while claiming “local”.

Operator actions (next 90 days)

- [OEM] Map DVA compliance by component, not by story. Identify weak links before audits do.

- [Battery Pack Maker] Prepare BPAN-ready data architecture: static + dynamic fields, BMS integration plan, telemetry.

- [Recyclers] Build capability to ingest BPAN-linked data and produce auditable recycling trails.

- [Investor] Add “compliance readiness” to diligence: systems, audits, traceability tooling, and data governance.

- [Policymaker] Publish implementation roadmap: timelines, enforcement, data governance, and interoperability standards.

- [Component Supplier] Align product roadmaps with localisation opportunities (power electronics, connectors, PCB assemblies) as ECMS approvals expand.

Questions for the Ecosystem

- Will Battery Pack Aadhaar become a real governance system or just a QR label layer?

- Should battery dynamic data be treated like vehicle telemetry: consent-based, but enforceable for safety events?

- If localisation enforcement tightens, do we see a short-term cost spike before scale economies kick in?