Each of our retrofitted models undergoes a rigorous certification process via ARAI/ICAT, ensuring full compliance with CMVR and AIS-123 Part 3 norms.

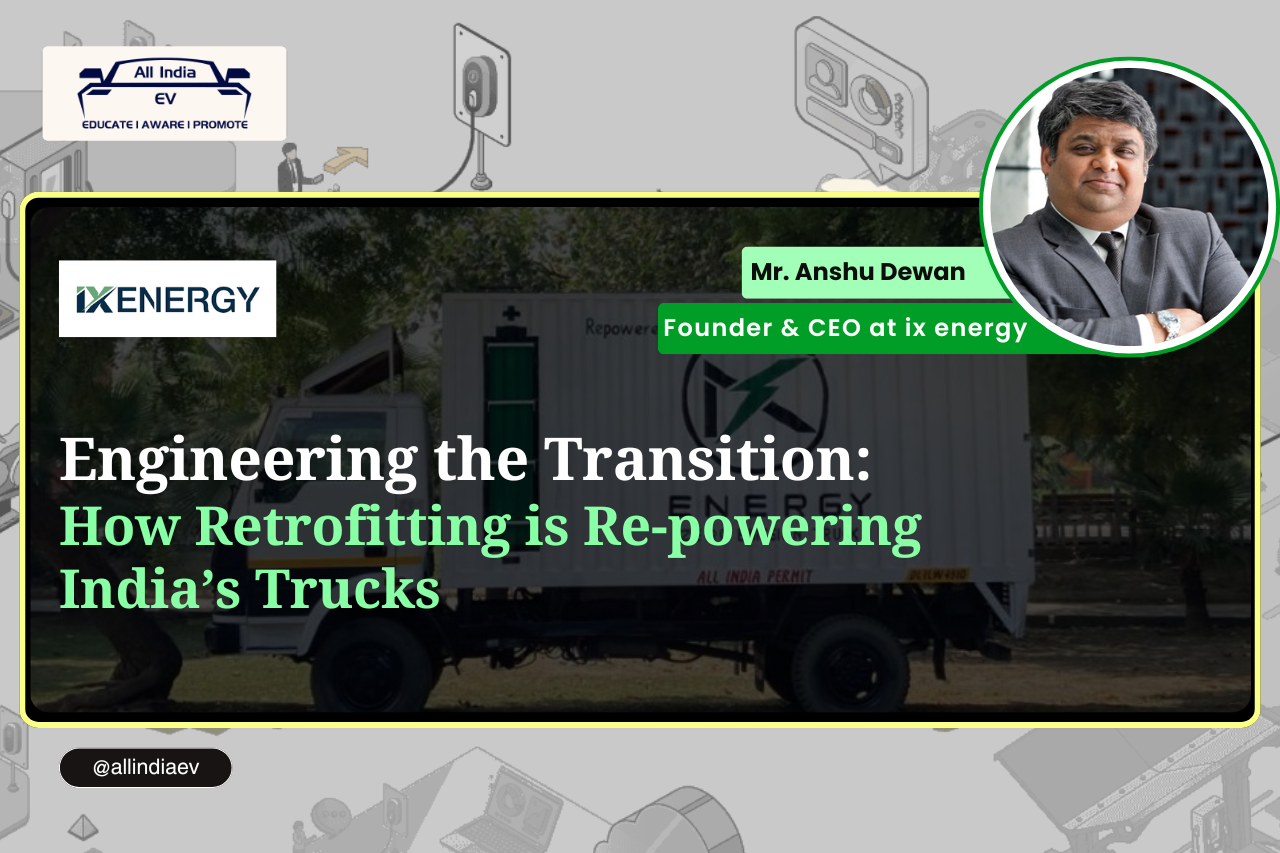

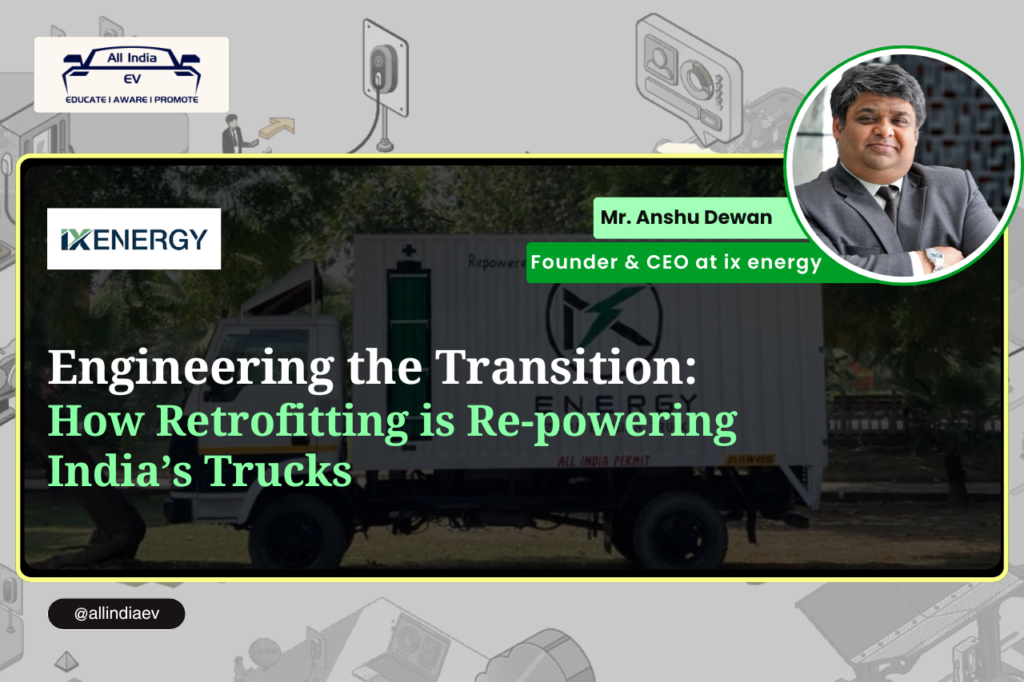

India’s journey toward sustainable mobility isn’t just about new EVs, it’s equally about transforming what’s already on the road.

At iX Energy, we believe truck retrofitting is a uniquely Indian innovation imperative. It’s where deep-tech engineering meets grassroots impact.

Battery Pack Design for Retrofitted Vehicles

Unlike new EVs, retrofits must work within the constraints of existing chassis and load-bearing designs.

At iX Energy, we custom-design battery packs (typically LFP chemistry) that are crash- safe, modular, and optimized for underbody or behind- cabin mounting—without compromising payload or vehicle balance.

Powertrain Integration

The retrofit process involves replacing the ICE drivetrain with an electric motor (typically PMSM or BLDC), power electronics, and a single-speed transmission. We engineer torque curves that match the performance needs of urban logistics and intra- city freight.

Retention of original differential and suspension ensures cost efficiency and rapid deployment.

Telematics & Smart Diagnostics

Our retrofit kits include an integrated telematics unit with real-time monitoring of SoC, vehicle health, location, and trip diagnostics. This not only improves operational visibility but also lays the groundwork for energy-efficient route planning and predictive maintenance.

Regulatory Certifications

Each of our retrofitted models undergoes a rigorous certification process via ARAI/ICAT, ensuring full compliance with CMVR and AIS-123 Part 3 norms.

Importantly, converted EVs are tested under the same protocols as new electric vehicles—including assessments for electrical safety, electromagnetic compatibility, thermal performance, and structural integrity.

This equivalence in testing underscores a critical point: retrofit EVs, when properly engineered and certified, are just as safe and reliable as factory-built EVs.

At iX Energy, we see this not only as a regulatory requirement, but as a design benchmark.

Design Constraints and Innovation

Working within the envelope of legacy diesel trucks— particularly LCVs like Tata 407, Eicher Pro series, and Mahindra Supro—means tight packaging, thermal management challenges, and variable wiring harnesses.

Our engineering teams have developed adaptable retrofit frameworks that reduce integration time from 60 to 25 days. Retrofitting isn’t just a lower-cost EV—it’s a leap in applied engineering, where each vehicle becomes a customized platform for sustainable transport.