The EV manufacturing industry is exploring alternatives to rare earth element (REE)-based permanent magnets.

As India’s electric vehicle (EV) sector accelerates towards a sustainable future, the need for alternatives to rare earth element (REE)-based permanent magnets has become a pressing concern. With domestic automakers like Tata Motors and Mahindra & Mahindra claiming around ₹246 crore under the central government’s production-linked incentive (PLI) scheme, the industry must now focus on reducing dependency on REEs to ensure long-term sustainability and supply chain stability.

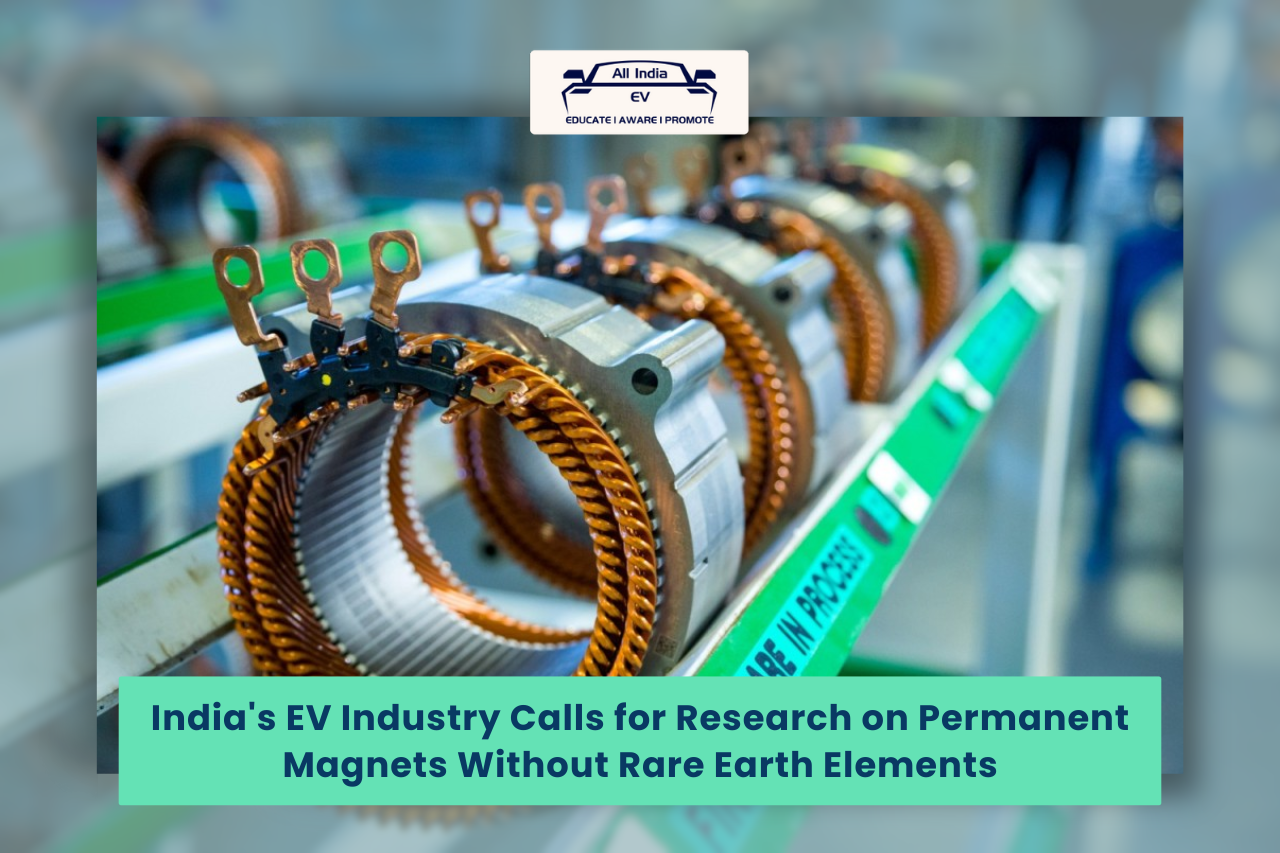

Why Are Permanent Magnets Important in EV Motors?

Permanent magnets play a crucial role in EV motors, a core component of electric vehicles. Currently, ferrite magnets are being explored as alternatives to REE magnets. However, a report published by IEEE Spectrum (July 2, 2024) highlights key challenges:

- Ferrite magnets are significantly heavier and increase vehicle weight.

- They are more prone to demagnetization, affecting motor performance.

- Ferrite-based motors remain at least 30% heavier than those using REE magnets, even with optimized designs.

Challenges of Ferrite Magnets in EV Motors

As India transitions to electric mobility, securing stable and eco-friendly supply chains is critical. The scientific limitations of ferrite magnets include:

- Higher electrical conductivity leading to unwanted heat buildup in motors, causing performance degradation.

- REE magnets, containing lanthanides, scandium, and yttrium, are more efficient but pose extraction and geopolitical challenges.

- China dominates the global REE supply chain, increasing India’s dependence on imports.

India’s Research & Development Efforts

Recognizing these concerns, India’s EV industry is actively seeking alternative materials. Research initiatives at institutions such as the Centre for Automotive Energy Materials at the International Advanced Research Centre for Powder Metallurgy & New Materials are exploring promising solutions.

According to IEEE Spectrum, potential alternatives include:

- High-silicon steel: Enhances magnetic efficiency in REE-free motors.

- High-conductivity copper alloys or ultraconducting copper strands: Reduce electrical losses and improve motor performance.

The Push for Self-Reliance in Clean Energy

The drive for alternative materials in EV motors aligns with India’s broader vision of self-reliance in the clean energy sector. As the country scales up EV adoption, reducing dependence on REEs will:

- Mitigate supply chain risks

- Boost domestic innovation in EV technology

- Promote environmental sustainability

The Road Ahead

The time is now for intensified research, government support, and industry collaboration to drive innovation in REE-free EV motors. As India leads the global electric mobility transition, sustainable and efficient solutions will define the future of clean transportation.

My company, NanoCrystal Magnetics, Inc. where I am a co-founder together with Dr. Ramesh Bgargava, has discovered a method to create strong permanent magnets without using any rare earths and using only readily available elements mined for over 100 years. Alexei Ekimov, now retired, our former CSO, was awarded the Nobel Prize in Chemistry in 2023 for his foundational discovery of the Quantum Dot which currently led to our current discovery which has been patented. As you would certainly know, China has a 92% worldcwide monopoly on High quality neodymium Permanent Magnets. We can break that monopoly and create a major export Industry for india. please visit: www

nanocrystalmagnetics.us ( note not dotcom) for further info.