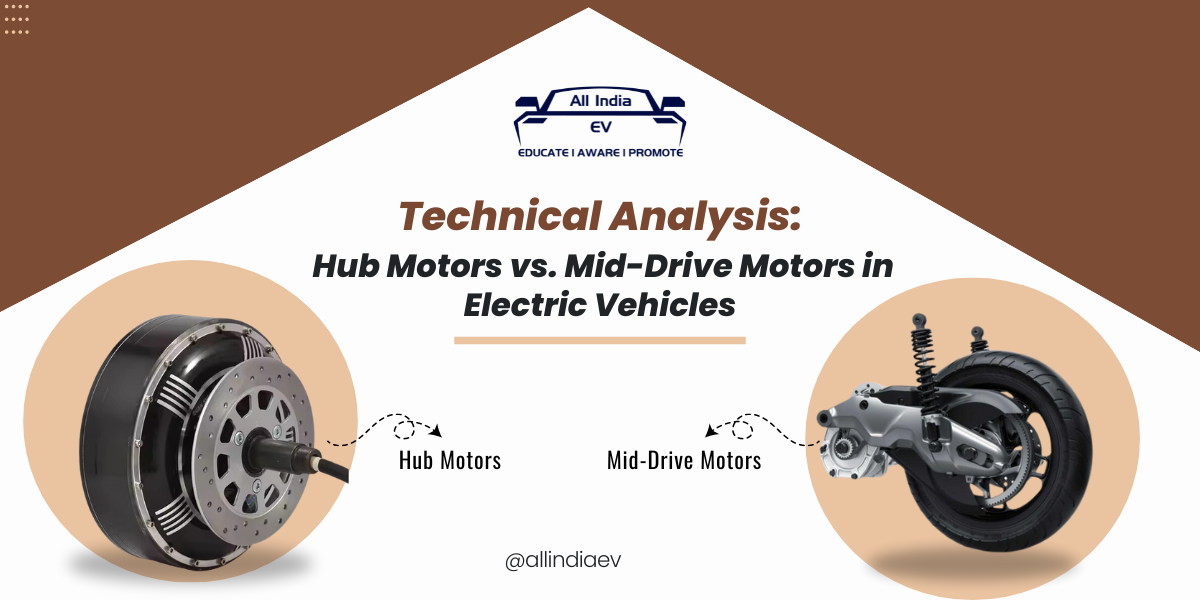

Technical Analysis: Hub Motors vs. Mid-Drive Motors in Electric Vehicles

Electric bikes (e-bikes) and electric motorcycles have become increasingly popular, and one of the most important decisions when choosing an e-bike or designing one is selecting the type of motor. Two common types of electric motors are hub motors and mid-drive motors, each with unique technical characteristics, advantages, and drawbacks. Understanding the technical differences between these two motor types is critical for optimizing performance, efficiency, and user experience in electric vehicles (EVs).

1. Design and Mechanism

- Hub Motors:

- Location: Hub motors are mounted directly in the hub of either the front or rear wheel.

- Operation: The motor is integrated with the wheel, driving it directly without involving any intermediary mechanical components like a chain or belt. This design allows the motor to apply torque directly to the wheel.

- Variants: Available in two variants — direct-drive and geared hub motors. Direct-drive hub motors are simpler but heavier, while geared hub motors have internal gears to increase torque at lower speeds.

- Mid-Drive Motors:

- Location: Mid-drive motors are positioned in the center of the bike, at the bottom bracket, between the pedals.

- Operation: These motors transfer power to the bike’s drivetrain (i.e., chain or belt), driving the rear wheel indirectly via the bike’s gears.

- Power Transfer: By using the bike’s gear system, mid-drive motors can optimize torque and speed depending on the terrain and the rider’s input.

2. Power and Efficiency

- Hub Motors:

- Efficiency: Hub motors are generally less efficient than mid-drive motors, especially at low speeds or on steep inclines. This is because hub motors directly drive the wheel, and their efficiency is not optimized by the bike’s gearing.

- Power Output: Hub motors typically have a steady, reliable power output but can struggle with power delivery in challenging conditions like steep hills. Geared hub motors can deliver better torque at lower speeds, but they are still less efficient compared to mid-drive motors.

- Mid-Drive Motors:

- Efficiency: Mid-drive motors tend to be more efficient due to their ability to leverage the bike’s gears. Riders can shift to a lower gear for climbing hills, maximizing the motor’s efficiency.

- Power Output: Mid-drive motors excel in producing higher torque and power on difficult terrain. By utilizing the bike’s gear system, mid-drive motors provide better hill-climbing ability and superior energy efficiency, translating to longer battery life in certain conditions.

3. Weight Distribution and Handling

- Hub Motors:

- Weight Distribution: Hub motors place additional weight at the wheel (either front or rear). This can negatively affect the bike’s handling, especially on uneven terrain. Front hub motors can cause front-heavy handling, while rear hub motors can make the rear of the bike feel heavy.

- Ride Stability: Hub motors are more stable for on-road riding, especially in flat terrain, but they are not ideal for off-road conditions due to the unbalanced weight distribution.

- Mid-Drive Motors:

- Weight Distribution: Mid-drive motors are positioned centrally on the bike, near the bottom bracket. This offers superior weight distribution and balance, making the bike feel more natural to ride and providing better handling, particularly in technical off-road scenarios.

- Ride Stability: With the motor’s weight positioned centrally, mid-drive systems provide better stability and control, improving the rider’s ability to maneuver the bike on different terrains.

4. Maintenance and Durability

- Hub Motors:

- Maintenance: Hub motors are often low-maintenance because they are sealed units. Geared hub motors might require some internal maintenance over time, but generally, the absence of many moving parts makes them relatively durable.

- Durability: Hub motors are isolated from the bike’s drivetrain, meaning there’s less wear and tear on the bike’s gears, chains, or derailleurs.

- Mid-Drive Motors:

- Maintenance: Mid-drive motors can place additional stress on the bike’s chain, gears, and drivetrain, leading to more frequent maintenance of these components. Chains and sprockets may wear out faster due to the high torque generated by the motor.

- Durability: While the motor itself is robust, the increased reliance on the bike’s mechanical components means that users need to pay more attention to drivetrain maintenance.

5. Torque and Performance

- Hub Motors:

- Torque: Hub motors typically provide less torque than mid-drive motors. Direct-drive hub motors, in particular, may struggle with torque at low speeds or when climbing hills.

- Performance on Inclines: Hub motors, especially the direct-drive variants, are not ideal for hilly terrains. Geared hub motors perform better on inclines, but still cannot match the torque efficiency of mid-drive systems.

- Mid-Drive Motors:

- Torque: Mid-drive motors deliver significantly higher torque due to their ability to engage with the bike’s gear system. This makes them particularly suited for steep inclines and uneven terrains.

- Performance on Inclines: Mid-drive motors outperform hub motors on hills, as the motor can work in conjunction with lower gears to optimize power output and efficiency.

6. Battery Consumption

- Hub Motors:

- Battery Efficiency: Hub motors are typically less efficient in terms of battery usage, especially when climbing hills or riding on rough terrains. The motor’s direct drive means that it is less adaptable to changing conditions.

- Range: Hub motors may result in shorter battery ranges in challenging conditions, as the motor consumes more power without the benefit of gear shifting.

- Mid-Drive Motors:

- Battery Efficiency: Mid-drive motors generally offer better battery efficiency, as they optimize power output based on the gear and terrain. By shifting to lower gears when needed, mid-drive motors can reduce the strain on the motor and extend the battery life.

- Range: Mid-drive systems often allow for longer ranges, especially in mixed-terrain environments, as the motor’s efficiency is maximized by utilizing the bike’s mechanical advantages.

7. Cost and Complexity

- Hub Motors:

- Cost: Hub motors are generally more affordable and simpler in design. They are a cost-effective solution for those looking for basic e-bikes for commuting or light recreational use.

- Complexity: Hub motors are mechanically simple and easier to install and maintain. For this reason, they are often found in lower-cost electric bikes.

- Mid-Drive Motors:

- Cost: Mid-drive motors tend to be more expensive due to their complex integration with the bike’s drivetrain and advanced torque-sensing technology.

- Complexity: Mid-drive motors are more complex to install and maintain, and they require a more robust bike frame to accommodate the motor. This can lead to higher initial costs and maintenance expenses over time.

Summary of Key Differences

| Feature | Hub Motors | Mid-Drive Motors |

| Location | Inside the front or rear wheel hub | Mounted at the bike’s bottom bracket |

| Efficiency | Less efficient, especially on inclines | More efficient due to gear integration |

| Torque | Lower torque, struggles on steep hills | High torque, excellent for steep inclines |

| Weight Distribution | Unbalanced, affecting handling | Centralized, better handling and stability |

| Maintenance | Low maintenance, no drivetrain wear | More drivetrain wear, requires regular upkeep |

| Battery Efficiency | Lower, especially on rough terrains | Higher, especially in varied terrains |

| Cost | Generally cheaper and simpler | More expensive and complex |

Conclusion

The choice between hub motors and mid-drive motors depends largely on the intended use of the electric vehicle. Hub motors are ideal for casual riders, urban commuters, and those seeking a low-cost, low-maintenance solution, particularly in flat terrain. In contrast, mid-drive motors are preferred by performance-focused riders who require higher torque, better handling, and superior efficiency, particularly in hilly or mixed terrains.

For users prioritizing power, hill-climbing ability, and range, the mid-drive motor is the superior option. However, for more straightforward, cost-effective use, hub motors can serve well.