Cell-to-Cell Insulation: Enhance EV Battery Safety

As electric vehicles (EVs) dominate automotive innovation, battery safety has emerged as the defining challenge of the decade. One concept stands out for its transformative potential: cell-to-cell insulation. Far from being a marginal design choice, it is the key to preventing catastrophic failures in EV battery packs.

Moving Beyond Delay: Cell-to-Cell Insulation Stops Thermal Propagation

Traditionally, thermal management strategies aimed to delay thermal propagation in the event of a cell failure. But in high-density EV battery packs, delay is no longer enough. A single cell undergoing thermal runaway can trigger a chain reaction, compromising the entire pack.

The solution? Don’t just delay thermal propagation. Stop it.

Cell-to-cell insulation acts as a thermal barrier, ensuring that heat from a failing cell doesn’t spread to adjacent cells. For manufacturers, this means the difference between a minor incident and a catastrophic fire.

The Material Science Behind Thermal Barriers

Not all thermal barrier materials are created equal. The EV industry now has a spectrum of options, each with trade-offs in thermal resistance, mechanical strength, cost, and ease of handling.

1. Aerogel Barriers

- Best for: Extreme thermal protection where space and weight are critical (aerospace, premium EV packs).

- Performance: Ultra-low thermal conductivity, with temperature resistance up to 650°C.

- Challenges: Brittle and fragile; requires support. High cost.

2. Silicone Compression Pads

- Best for: Thermal interface and insulation at contact zones (e.g., between cells and cooling plates).

- Performance: Moderate thermal insulation; excellent electrical insulation.

- Challenges: Limited temperature resistance (~200–250°C); heavier than aerogels.

3. Resin-Impregnated Mica

- Best for: All-round fire barriers between cells/modules.

- Performance: Withstands up to 1000°C; excellent fire resistance; strong and stable under heat.

- Challenges: Medium weight; cost-effective.

4. Mica Sheets

- Best for: High-temperature, rigid insulation, especially in structural or terminal zones.

- Performance: Handles up to 1000°C; excellent electrical insulation.

- Challenges: Brittle and prone to cracking; brittle during handling.

Comparing Thermal Barrier Options

| Factor | Aerogel | Silicone Pad | Resin Mica | Mica Sheet |

| Thermal Insulation | Best-in-class | Moderate | Good | Good |

| Temp Resistance | Up to 650°C | ~200–250°C | Up to 1000°C | Up to 1000°C |

| Mechanical Strength | Brittle (needs support) | Soft, flexible | Strong, heat-stable | Brittle |

| Fire Resistance | Non-combustible | UL94-V0 grades | Excellent, non-flammable | Excellent |

| Electrical Insulation | Good | Excellent | Excellent | Excellent |

| Cost | High | Moderate | Cost-effective | Low to moderate |

| Weight | Ultra-light | Heavier than aerogel | Medium | Medium |

| Ease of Handling | Dusty, fragile | Conformable, easy cut | Easy to cut and layer | Brittle when cut |

The Road Ahead

As India accelerates its EV ambitions, battery safety innovations like cell-to-cell insulation must take center stage. Regulations are tightening, and consumer confidence hinges on manufacturers implementing robust thermal management solutions. The choice of thermal barrier material isn’t just a technical detail; it’s a strategic decision with far-reaching implications for performance, safety, and brand reputation.

The future is electric. Let’s ensure it’s also safe.

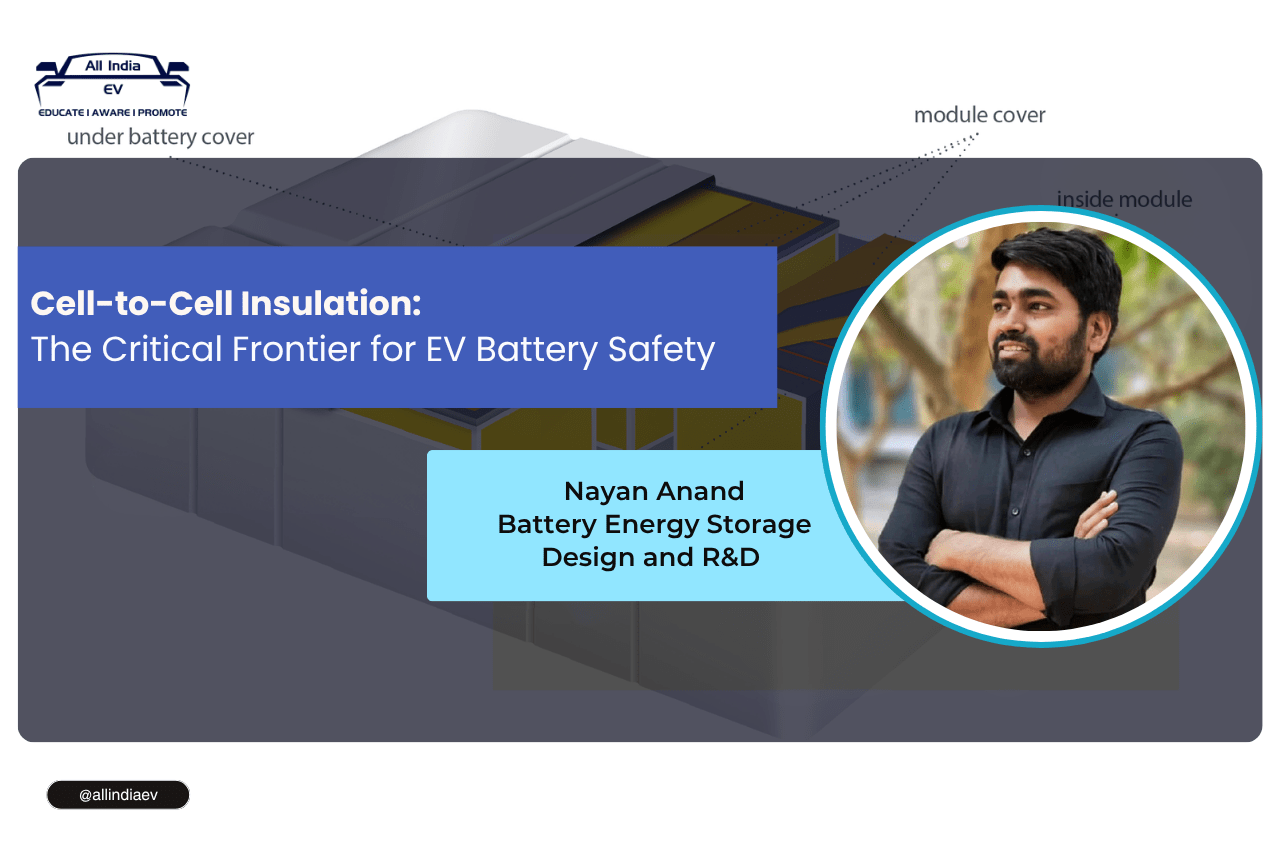

About The Author

Nayan Anand: nayan.anand94@gmail.com

As a Battery Energy Storage Design and R&D professional passionate about sustainable energy, I’ve dedicated my career to building safer, more efficient, and innovative energy storage solutions. From pioneering India’s indigenously developed Al-Air cells and batteries to filing multiple design patents in metal-air technology, I’ve always believed that the smallest design decisions can make the biggest impact.

With hands-on experience across BESS for grid applications, mobility, and next-gen chemistries, I thrive at the intersection of creativity, engineering, and real-world impact. I’m driven by the mission to create technologies that not only solve technical challenges but also contribute to a cleaner, more resilient future.