EV Startup Loans by Credifin supporting EV growth

India’s EV Backbone Needs Builders — EV Startup Loans by Credifin Are Backing Them The…

Is India’s EV Industry a Rental Dream, Made in China, or Assembled in India?

Is India's EV Industry a Rental Dream, Made in China, or Assembled in India? The…

MG Motors and Strompuls Collaboration

MG Motors Teams Up with Strompuls to Boost EV Versatility with Indigenous V2L and V2V…

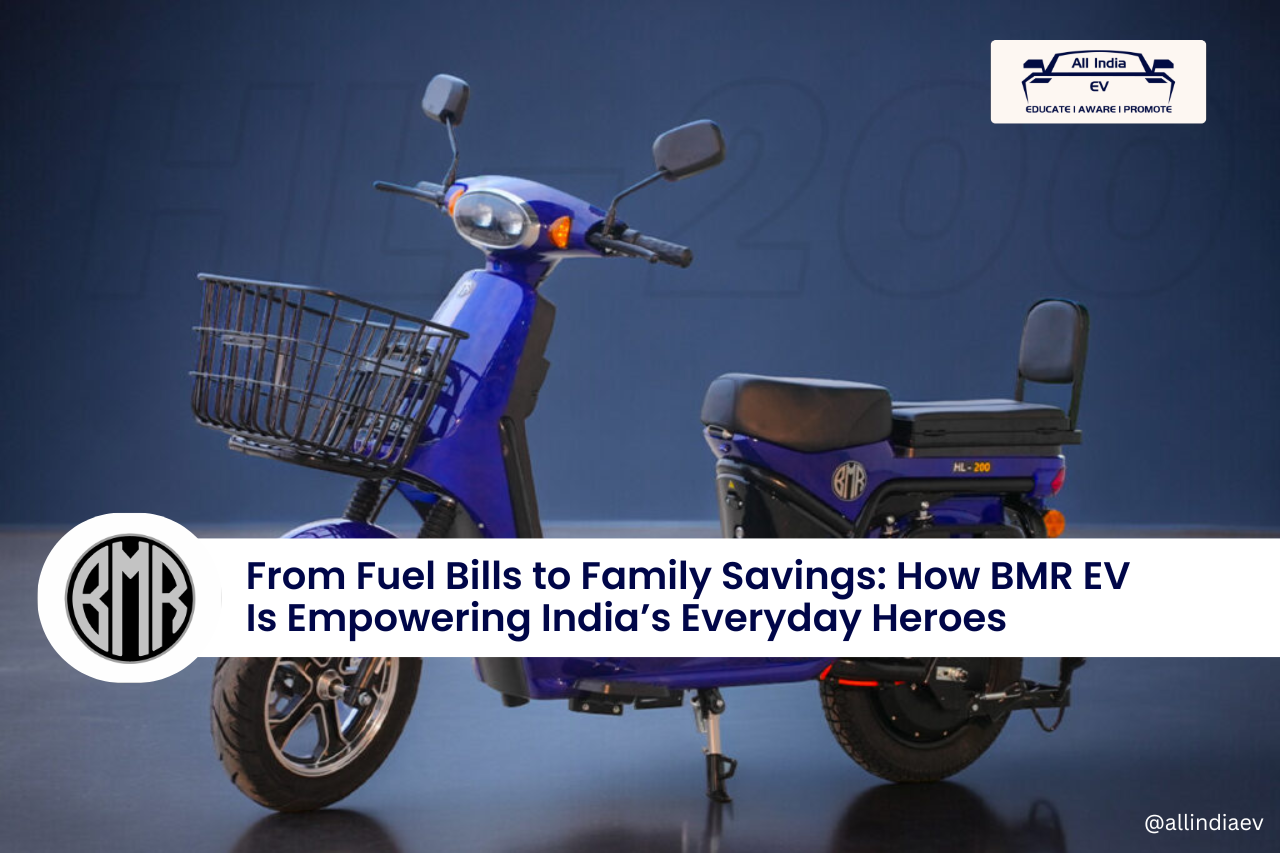

From Fuel Bills to Family Savings: How BMR EV Is Empowering India’s Everyday Heroes

From Fuel Bills to Family Savings: How BMR EV Is Empowering India’s Everyday Heroes Chittoor…

OMCs add 10,000+ EV charging stations in FY25

Indian Oil Marketing Companies added 10,000+ EV charging stations in FY25 In a big boost…

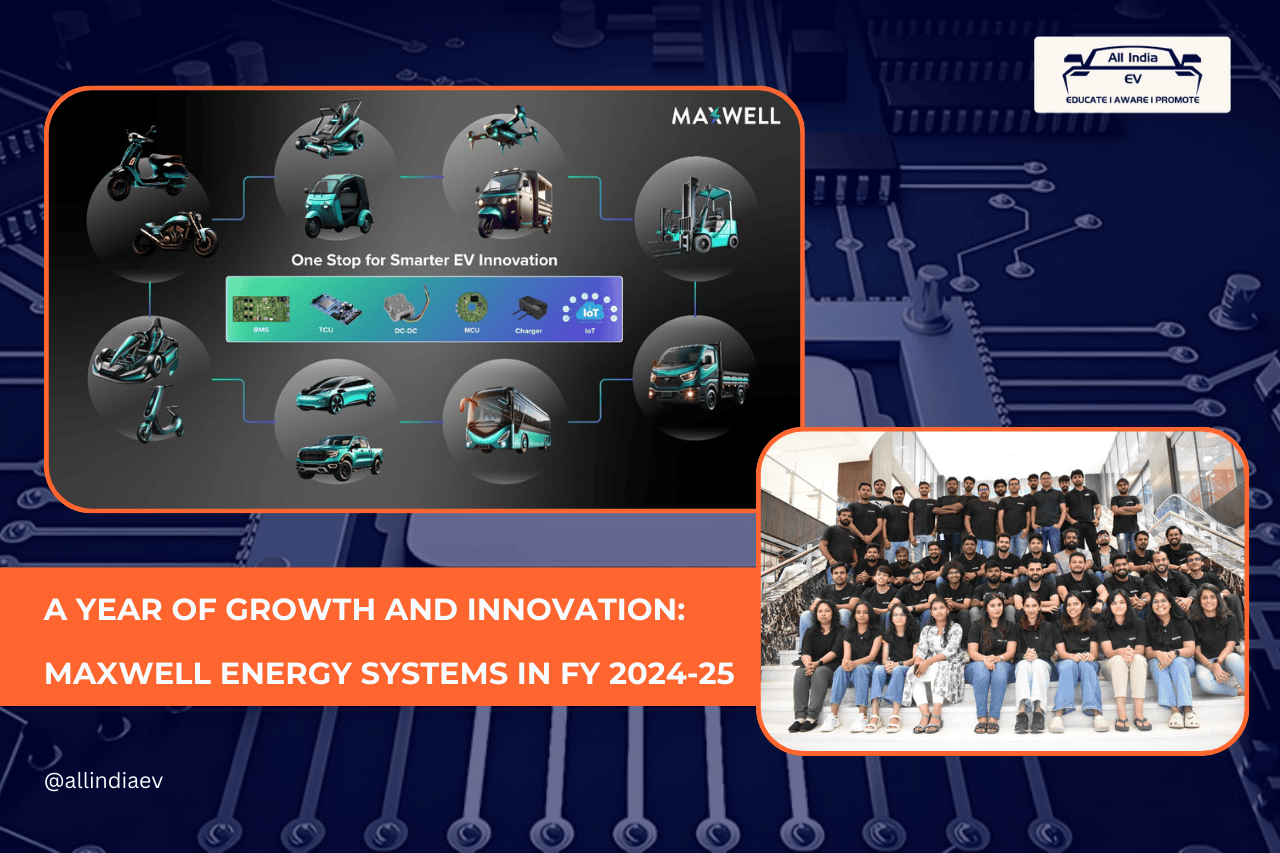

A Year of Growth and Innovation: Maxwell Energy Systems in FY 2024-25

A Year of Growth and Innovation: Maxwell Energy Systems in FY 2024-25 FY 2024-25 has…

Vehicle-to-Grid (V2G): The Future of Smart EV Charging in India

Vehicle-to-Grid (V2G): Unlocking the Future of Smart EV Charging in India The electric vehicle (EV)…

EV Financing in last 12 months in India

Powering the Charge: The Pivotal Role of Financing Institutes in India’s Electric Vehicle Market Growth…

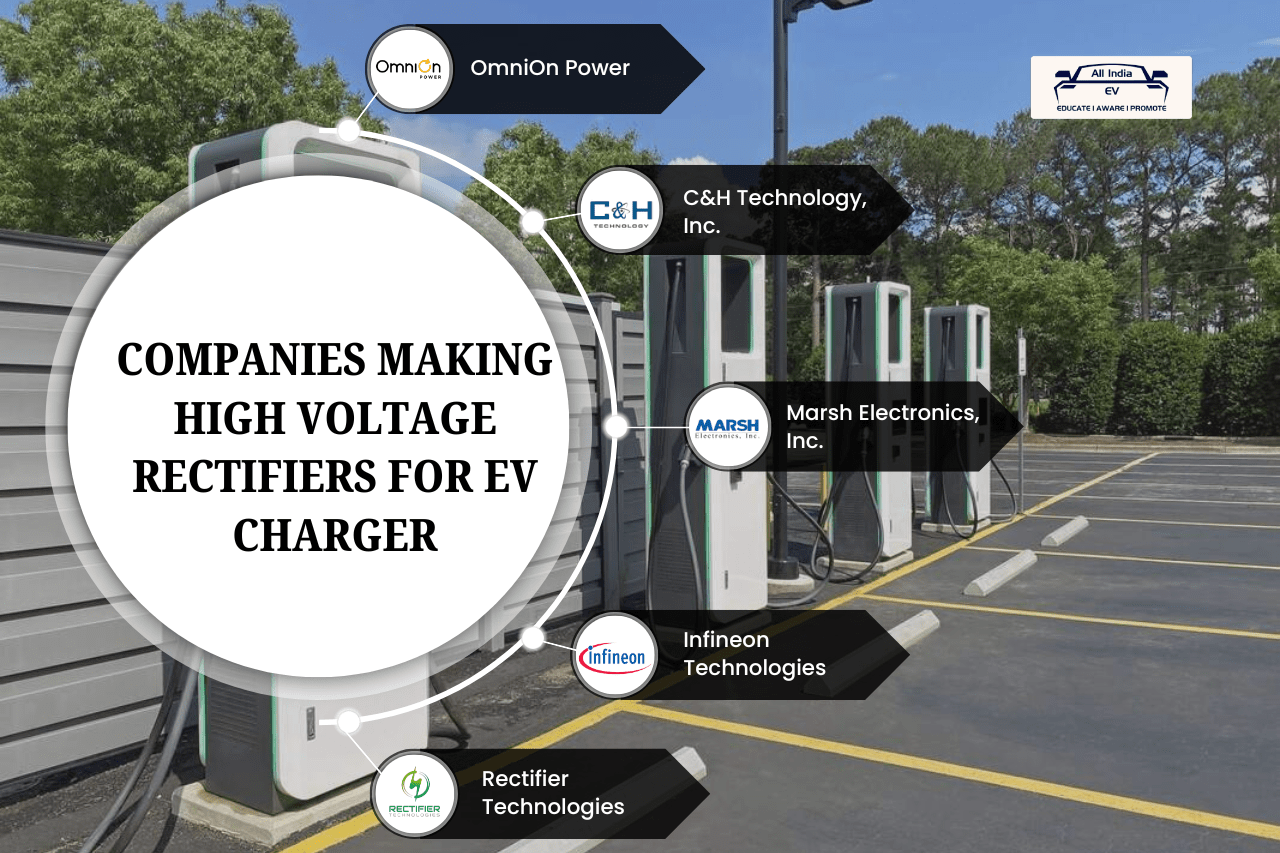

Companies making high voltage rectifiers for ev chargers

Companies making high voltage rectifiers for ev chargers Electric vehicle (EV) fast chargers require powerful…

5 mutual funds charging up on EV stocks in 2025

5 mutual funds charging up on EV stocks in 2025 India's electric vehicle (EV) sector…

India to Revise EV Policy as Tesla Prepares for Market Entry

Indian Govt May Tweak EV Policy Again as Tesla Gears Up for India Entry India’s…

Euler Motors and Tata Power Renewables collaborated to Boost EV Adoption

Euler Motors and Tata Power Renewables sign MoU to Accelerate EV adoption with Fast-Charging Infrastructure…