Battery Operated Electric Vehicles (BEVs): An In-Depth Overview

Battery-Operated Electric Vehicles (BEVs) are revolutionizing the transportation landscape, offering an environmentally friendly and cost-effective alternative to traditional internal combustion engine (ICE) vehicles. BEVs operate solely on electricity, relying on rechargeable batteries as their primary source of energy.

This article, written by Arpit Bohre, provides an in-depth examination of the essential components and working mechanisms of BEVs.

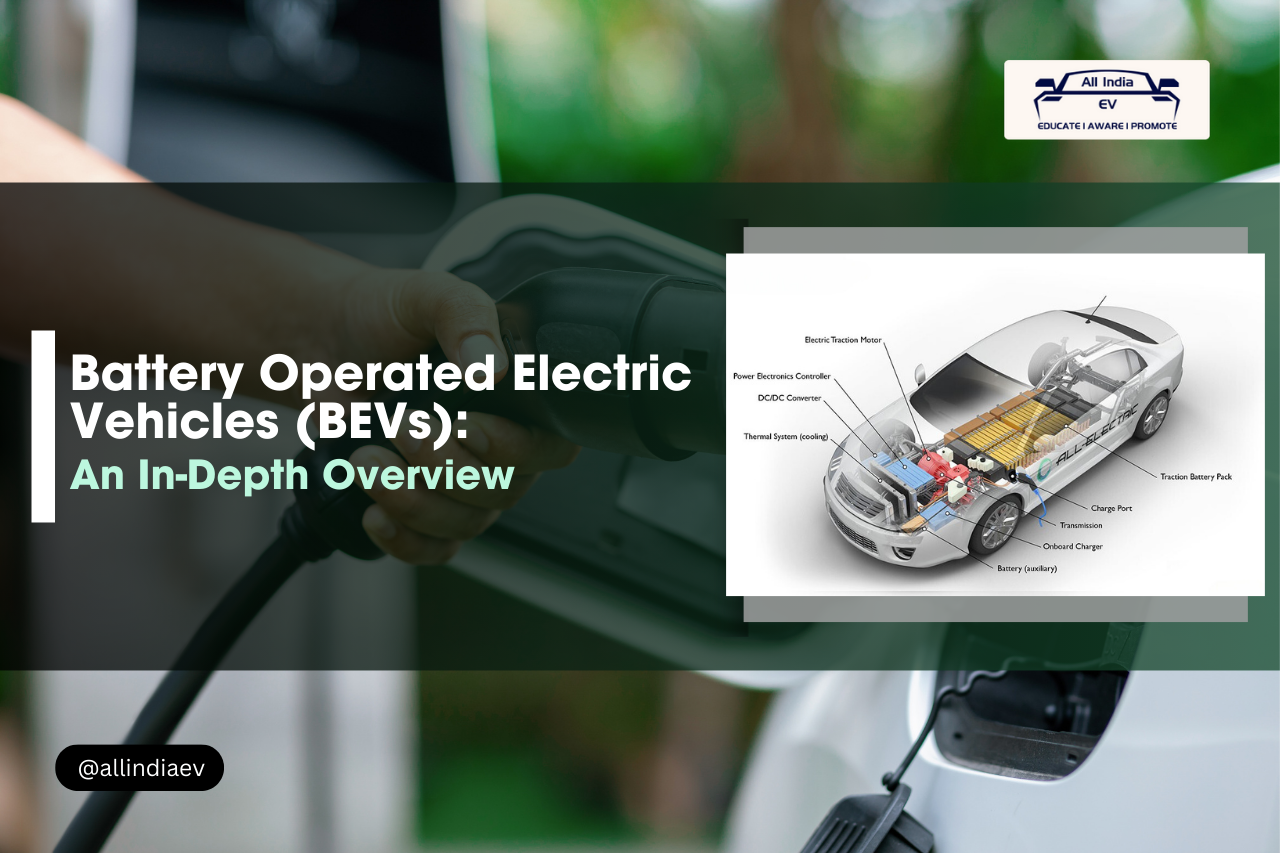

Key Componenets of BEVs

1. Traction Batteries

Traction batteries are the heart of a BEV, responsible for storing and supplying electric power to the motor. These batteries operate by storing electrical energy in chemical form, which is then converted back into electricity when the vehicle is in motion. Key characteristics include energy density, charge/discharge rates, and cycle life, all of which impact the vehicle’s range and performance.

Various types of traction batteries are used in BEVs, including:

▶️Lithium-ion (Li-ion) Batteries: Known for their high energy density and efficiency, Li-ion batteries are widely used in BEVs like the Tesla Model 3 and Nissan Leaf.

▶️ Lithium Iron Phosphate (LFP) Batteries: LFP batteries offer excellent safety and longevity, making them ideal for EVs such as the Tesla Model S and Chinese EV models.

▶️ Solid-State Batteries: A developing technology with greater energy density, solid-state batteries have the potential to revolutionize BEVs in the future due to their stability and lightweight.

2. Electric Motors

Electric motors convert electrical energy from the traction battery into mechanical energy, propelling the vehicle. The operation of electric motors is based on electromagnetic induction, where electric current flowing through a coil in a magnetic field generates force. Types of electric motors commonly used in BEVs include:

🚩 Permanent Magnet Synchronous Motors (PMSM): Used in BEVs like the Tesla Model 3, PMSMs are efficient, powerful, and have a high power-to-weight ratio.

🚩 Induction Motors: Found in vehicles like the Tesla Model S, induction motors are rugged, affordable, and can operate over a wide range of speeds.

🚩 Brushless DC Motors (BLDC): Popular in smaller electric vehicles, BLDC motors have low maintenance costs and high efficiency.

Each motor type offers distinct advantages, and manufacturers select them based on vehicle requirements, such as performance, durability, and cost.

3. Power Converters

Power converters in BEVs manage the flow and transformation of electric power from the battery to various components. The key power converters in BEVs are:

🎯 DC-DC Converters: Convert high-voltage DC from the battery to lower voltages, supplying power to auxiliary systems like lighting and infotainment.

🎯 Inverters: Convert DC power from the battery into AC power required by the motor. Modern BEVs use advanced inverters capable of fine-tuning voltage and current, optimizing efficiency.

🎯 AC-DC Converters: Employed in charging systems to convert AC from charging stations to DC for battery storage.

These converters ensure efficient energy management, contributing to the overall performance and range of BEVs.

4. Controllers

Controllers in BEVs serve as the vehicle’s brain, regulating power distribution and controlling the speed, torque, and operational parameters of the motor. Types of controllers in BEVs include:

✔️ Motor Controllers: Manage motor speed and torque by controlling voltage and current levels, facilitating smooth acceleration and deceleration.

✔️ Battery Management System (BMS): Ensures safe and efficient battery operation by monitoring temperature, state of charge (SOC), and state of health (SOH), thus extending battery life.

Controllers improve the driving experience by maintaining precise control over powertrain functions and ensuring optimal efficiency.

5. Onbound Chargers

Onboard chargers convert AC from external sources to DC, enabling efficient battery recharging. These chargers vary in power capacity, impacting the charging speed. Types of onboard chargers include:

▶️ Single-Phase Chargers: Typically found in home charging setups, they offer moderate charging speeds.

▶️ Three-Phase Chargers: Used in commercial charging stations, these provide faster charging for high-capacity batteries.

The onboard charger determines the compatibility of a BEV with various charging sources and plays a crucial role in the convenience of EV charging.

6. Charging Ports

Charging ports connect BEVs to external power sources, and their type and compatibility affect charging speed. Standard charging port types include:

📌 Type 1 (J1772): Widely used in North America.

📌 Type 2 (Mennekes): Common in Europe and supports higher power delivery.

📌 CHAdeMO and CCS (Combined Charging System): Fast-charging systems used in many

BEVs globally.

Different charging ports support varying power levels, allowing for versatile charging solutions depending on the vehicle’s requirements and available infrastructure.

Working Mechanism of a BEV

The working mechanism of a BEV involves a seamless flow of electrical energy from the traction battery to the motor, facilitating vehicle movement. Here’s a step-by-step overview of how BEVs operate:

▶️ Energy Storage: The BEV’s traction battery stores electricity as chemical energy, which is then converted to electrical energy to power the motor.

▶️ Power Distribution: When the driver presses the accelerator, the controller regulates the power flow, determining the motor’s speed and torque.

▶️ Electric Motor Operation: The inverter converts DC from the battery to AC, allowing the motor to create the required mechanical force for propulsion.

▶️ Regenerative Braking: During braking, the motor reverses to act as a generator, converting kinetic energy back into electrical energy, which is stored in the battery. This process extends the BEV’s range by harnessing energy that would otherwise be lost.

▶️ Power Management: Controllers and converters work in sync to optimize energy distribution, ensuring that auxiliary systems receive adequate power without compromising driving efficiency

Battery-operated EVs continue to gain momentum, offering a sustainable, zero-emission solution to modern mobility challenges. With advancements in battery chemistry, motor technology, and charging infrastructure, BEVs are not only redefining the automobile industry but also paving the way toward a cleaner and greener future.