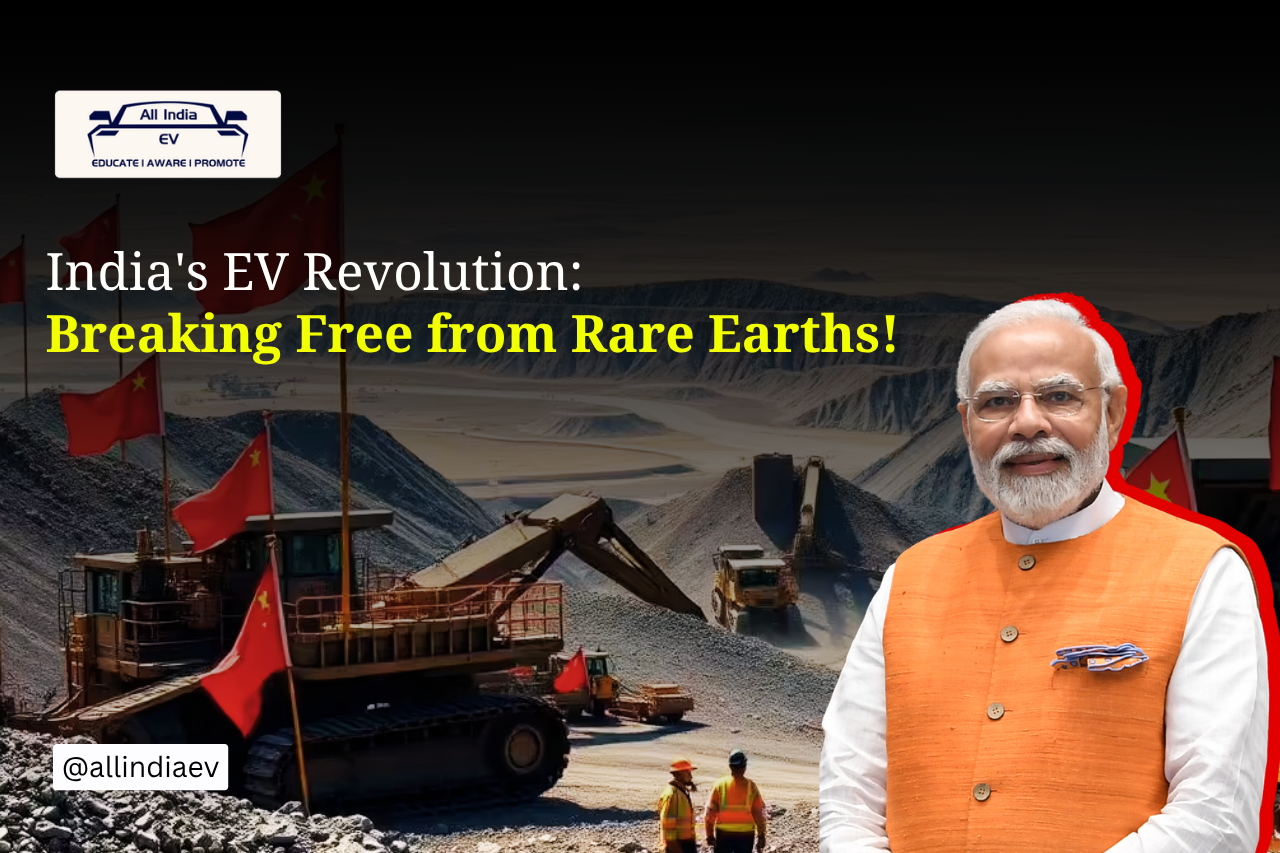

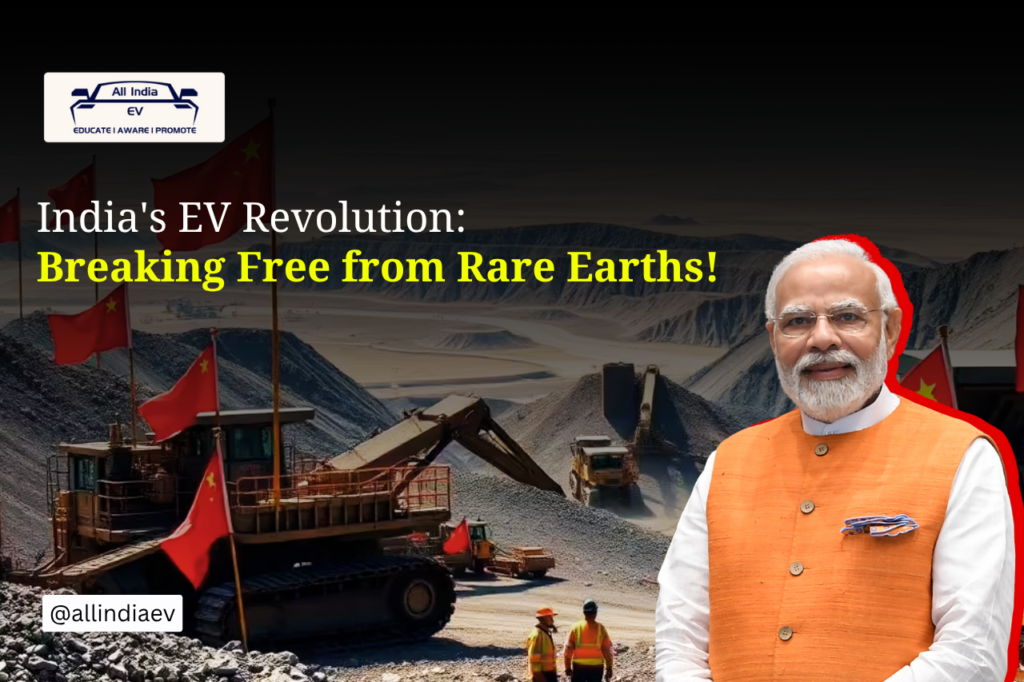

India’s EV Sector Reset: Scaling Rare-Earth-Free Tech to Cut China Dependency and Boost Domestic EV Manufacturing

In a bold move to counter global supply chain risks, India is resetting its electric vehicle (EV) powertrain strategy by developing motors that are independent of rare earth magnets—a critical component historically dominated by China, which controls over 90% of global rare earth processing.

Rare Earth Shortage Now a Real-Time Crisis

The urgency is real. In May 2025, a leading Indian two-wheeler manufacturer issued a warning that production disruptions could begin as early as July due to shortages in rare earth magnets. This is not a future threat—it is already impacting delivery timelines and manufacturing cycles.

Despite holding the fifth-largest rare earth reserves in the world, India processes almost none of it domestically. Until recently, Indian OEMs were entirely reliant on importing finished magnets from China, exposing them to geopolitical and economic vulnerabilities.

A Radical Rethink: Indigenous Powertrain Innovation

Now, a new generation of Indian engineers is changing the game. Instead of trying to fix the supply chain, they’re designing motors from scratch that don’t use rare earth elements at all. These motors use locally available materials like steel, copper, and aluminium, and are tailored specifically for Indian two- and three-wheeler platforms.

This isn’t just a swap—it’s a full-stack redesign of EV powertrains, engineered for India’s real-world driving conditions: high humidity, dusty environments, stop-and-go city traffic, and mixed urban-rural terrain. Pilot testing is already underway, with commercial rollout expected within 12–18 months.

Closing the Performance Gap—Without Rare Earths

What once seemed like a technical compromise is no longer the case. Advanced reluctance motors, ferrite-based designs, smart control systems, and high-grade silicon steel are now capable of matching the torque and efficiency of rare-earth-based motors—without the environmental damage or fragile supply chains.

Even more, these motors are easier to maintain and better suited to India’s cost-sensitive, service-heavy market.

Designed for India, Built to Scale

What gives India an edge is its ability to scale rapidly. These motors are not retrofits—they’re clean-sheet designs for Indian road and rider conditions. With localised supply chains, low tooling costs, and a strong base of domestic two- and three-wheeler OEMs, India is uniquely positioned to industrialise rare-earth-free motors faster than any other country.

Policy and R&D Driving the Shift

Government backing is accelerating this transition. Under the Production Linked Incentive (PLI) scheme, fresh investments are flowing into magnet-free technologies. Meanwhile, academic-industry collaborations are pushing innovations from the lab to the streets at record speed.

By investing in rare-earth-free EV powertrains, India is building entire new value chains—from raw materials to manufacturing and control software—leading to domestic job creation, IP ownership, and long-term industrial resilience.

From Strategic Dependence to Technological Leadership

This is more than a technical evolution—it is a strategic reset. India is moving from rare earth dependency to technological independence, laying down a path to leadership in global EV innovation.

By scaling up rare-earth-free powertrains, India can eliminate a key vulnerability, build a resilient domestic EV ecosystem, and create a globally competitive clean mobility solution.

India’s EV revolution is entering its most defining phase—designed at home, built for the world.