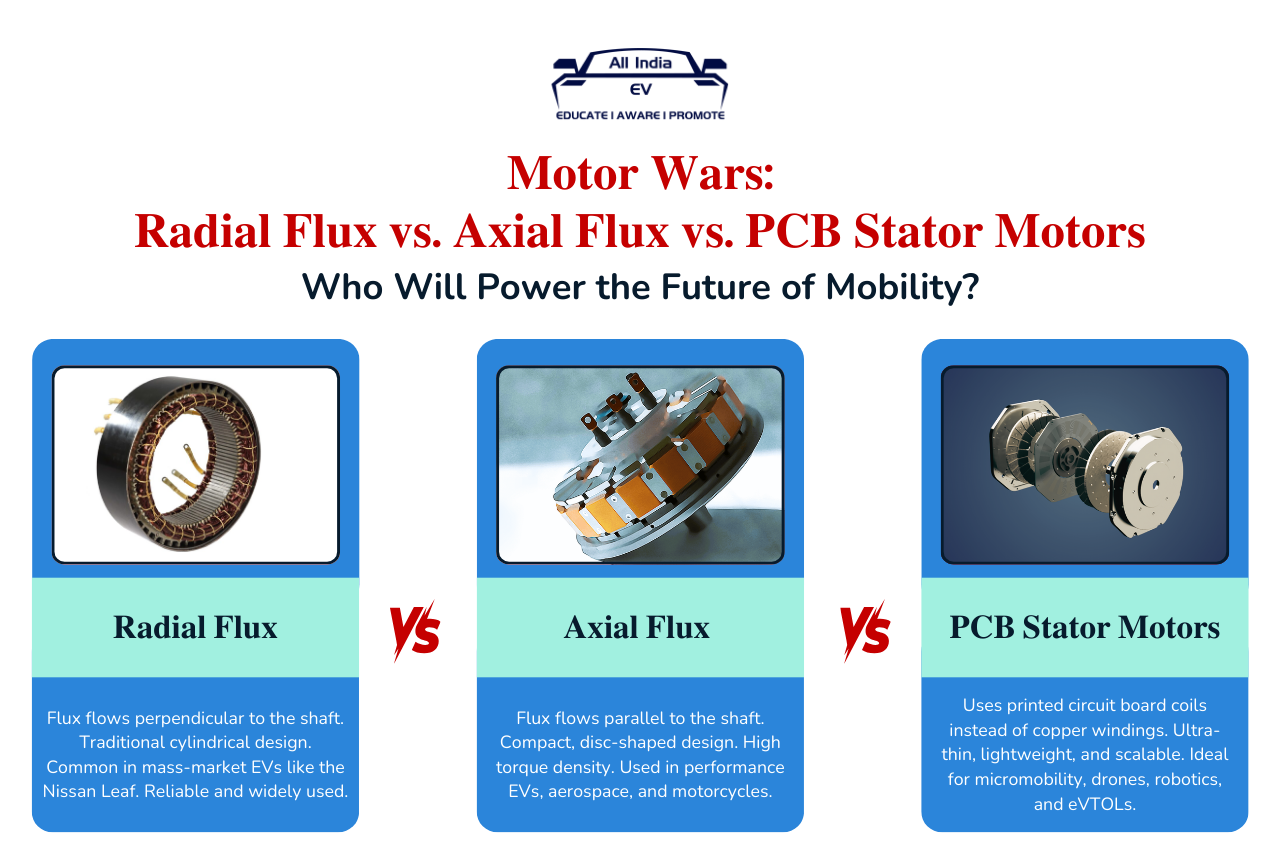

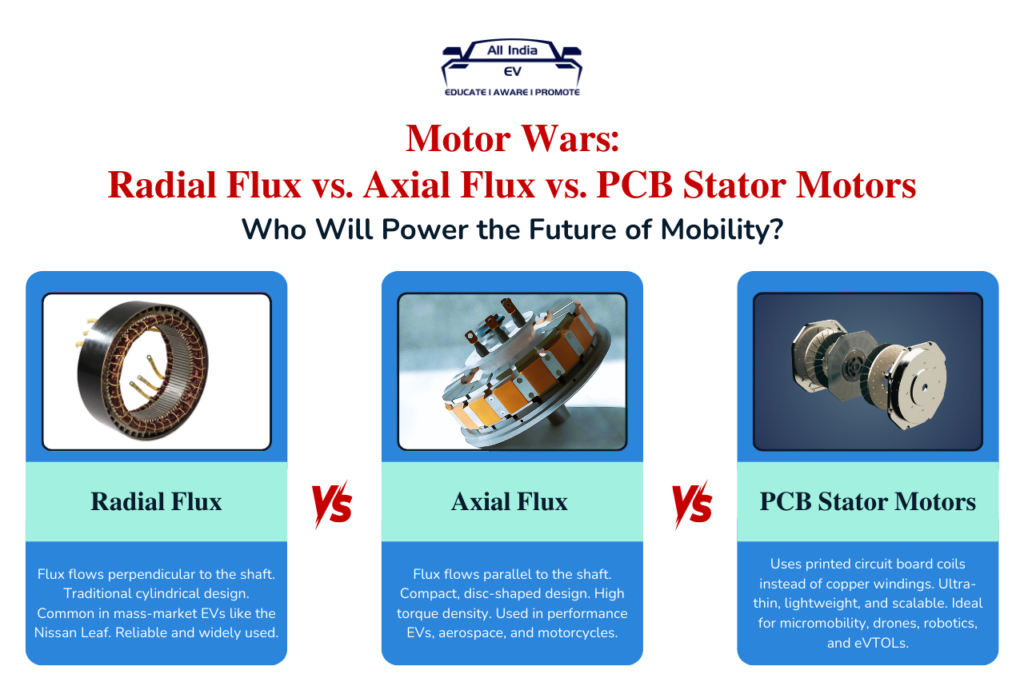

Motor Wars: Radial Flux vs. Axial Flux vs. PCB Stator—explore the battle for EV motor supremacy.

India EV, we’re constantly tracking the innovations that are shaping the future of electric mobility—not just in India, but globally. Today, we explore one of the most fundamental battlegrounds of EV design: Electric Motors. As manufacturers race toward better performance, higher efficiency, and more compact systems, a fierce competition is unfolding between Radial Flux Motors, Axial Flux Motors, and the emerging PCB Stator-based Motors.

⚙️ Radial Flux Motors: The Industry Standard

Radial flux motors are the backbone of today’s EV industry. In this configuration, magnetic flux flows perpendicular to the motor shaft. These motors use a cylindrical rotor and stator setup, and their reliability has made them the go-to solution for mass-market EVs like the Nissan Leaf.

✅ Proven, mass-manufactured

✅ Cost-effective

✅ Widely used across mainstream automotive platforms

Despite their dominance, radial flux motors face limitations in terms of weight, scalability, and torque density.

🌀 Axial Flux Motors: Compact Power for Performance

Now enter the Axial Flux Motor—the compact, disc-shaped alternative. Here, the magnetic flux flows parallel to the shaft. This design allows for higher torque density in a smaller footprint, making it ideal for performance EVs, electric motorcycles, aerospace applications, and more.

⚡ Compact and lightweight

⚡ Higher torque per kg

⚡ Popular among startups and high-performance OEMs

Axial flux motors are already being used in high-end systems like the Koenigsegg Quark E-Motor, which integrates axial flux with advanced lightweight designs.

🔬 PCB Stator Axial Flux Motors: A Disruptive Contender

At the bleeding edge of motor innovation is a newer class: PCB Stator Axial Flux Motors. These motors replace traditional copper windings with printed circuit board (PCB) coils, leading to ultra-thin, energy-efficient, and mass-scalable designs.

🌐 First pioneered by companies like Turntide Technologies and Linear Labs, and now backed by MIT spin-offs such as Infinitum Electric, this technology is gaining serious momentum.

🌍 Global Momentum Behind PCB Stator Technology

🔹 Infinitum Electric raised $185 million to scale PCB motors for HVAC and industrial systems

🔹 Turntide Technologies focuses on smart motor systems using axial PCB designs to cut energy usage

🔹 Koenigsegg’s Quark Motor combines axial flux and PCB elements to reduce weight in hybrid hypercars

PCB motors are particularly promising for micromobility, drones, robotics, and even eVTOLs (electric vertical take-off and landing aircraft).

🔋 So, What’s Next for India’s EV Landscape?

While Radial Flux Motors currently dominate Indian EV platforms, especially two- and three-wheelers, we at India EV believe that Axial Flux and PCB motors are poised to revolutionize the industry with their lightweight, scalable, and energy-efficient characteristics.

As India pushes toward electrifying not just passenger cars but also logistics, fleets, and even urban air mobility, these next-gen motors could redefine the country’s EV architecture.

🧠 Final Thoughts from India EV

This isn’t just a tech comparison—it’s a vision of how mobility in India can evolve. From crowded urban streets to clean energy air corridors, the future is electric. And the motor you choose might just determine how far, how fast, and how efficiently we get there.

Which motor tech are you betting on for India’s EV revolution?