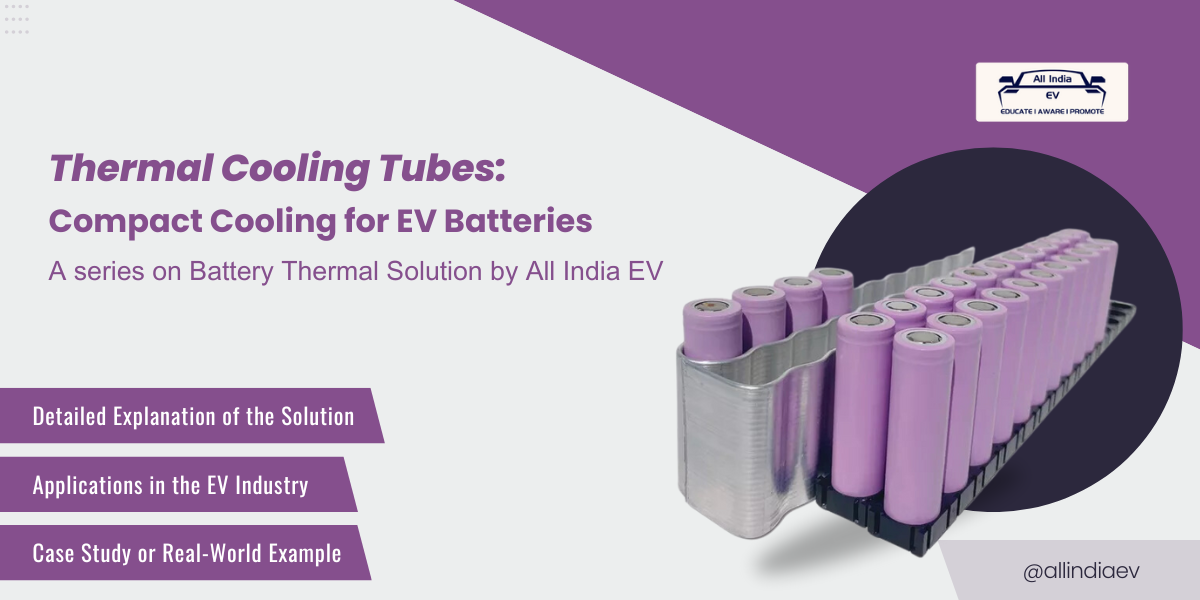

Thermal Cooling Tubes: Compact Cooling for EV Batteries

Electric vehicles (EVs) have seen a surge in popularity due to their environmental benefits and advancements in battery technology. However, one of the critical challenges in EV development is managing the heat generated by the battery pack during operation. Excessive heat can lead to reduced battery life, performance degradation, and even safety hazards. Thermal cooling tubes offer a promising solution to this problem, providing efficient and compact cooling for EV batteries.

Detailed Explanation of the Solution

Thermal cooling tubes are essentially conduits that circulate coolant fluid directly around the individual battery cells within a pack. This design allows for localized cooling, preventing hotspots that can develop in large and densely packed battery configurations. The coolant fluid, typically a mixture of water and glycol, absorbs heat from the battery cells as it flows through the tubes. This heat is then dissipated elsewhere in the vehicle’s cooling system.

Applications in the EV Industry

Thermal cooling tubes are particularly well-suited for electric SUVs, high-performance electric cars, and other vehicles that require high levels of power and torque. These vehicles often have larger battery packs to meet their performance demands, which can generate more heat during operation. Excessive heat can lead to reduced battery capacity, decreased range, and even safety hazards.

Electric SUVs: SUVs are typically heavier and have more powerful motors than smaller cars, leading to increased heat generation. Thermal cooling tubes can effectively manage this heat, ensuring that the battery pack operates at optimal temperatures even during demanding driving conditions.

High-Performance Electric Cars: Sports cars and other high-performance EVs often push their batteries to their limits. Thermal cooling tubes can help to prevent overheating, allowing these vehicles to maintain their peak performance and acceleration capabilities.

Commercial Vehicles: Electric trucks and buses face unique challenges in terms of heat management due to their heavy loads and extended operating cycles. Thermal cooling tubes can help to ensure that the batteries in these vehicles remain cool and efficient, even under demanding conditions.

Fast Charging: Rapid charging stations can generate significant heat in EV batteries. Thermal cooling tubes can help to dissipate this heat quickly, allowing for faster charging times without compromising battery health.

In addition to these specific applications, thermal cooling tubes can also be used in other EV types, such as electric motorcycles and electric scooters. The versatility of thermal cooling tubes makes them a valuable tool for managing heat in a wide range of electric vehicles.

Companies Involved

Several companies have played a significant role in the development and manufacturing of thermal cooling tubes for the electric vehicle (EV) industry.

We discuss about the following companies:

- Valeo: A global leader in automotive components and systems, has been at the forefront of this technology. Their thermal cooling tubes are designed to provide efficient and reliable heat management for EV batteries, ensuring optimal performance and longevity.

- Hanon Systems: Major player in the automotive industry, specializes in thermal solutions. They have developed innovative thermal cooling tube designs that are tailored to meet the specific needs of different EV models. Hanon Systems’ products are known for their high quality and reliability.

- Modine Manufacturing: a global leader in thermal management solutions, has also made significant contributions to the EV industry. Their thermal cooling tubes are designed to provide efficient heat dissipation while minimizing system complexity and cost. Modine’s expertise in thermal engineering has enabled them to develop products that meet the demanding requirements of the EV market.

Challenges and Limitations

Despite their benefits, thermal cooling tubes do present some challenges. The installation of these tubes requires precise engineering to ensure proper heat dissipation and prevent fluid leaks. Any misalignment or improper installation can compromise the effectiveness of the cooling system and potentially lead to overheating or other problems.

We can summarize the limitation as:

- Complexity and Cost: Integrating thermal cooling tubes into an EV battery pack can be more complex and expensive than other cooling methods. The tubes themselves, along with the necessary plumbing and control systems, can add to the overall weight and cost of the vehicle. Maintenance and repair of thermal cooling systems can also be more complex and expensive than traditional cooling systems.

- Long-Term Durability: Thermal cooling tubes may become clogged or corroded over time, reducing their effectiveness. Regular maintenance and inspections are necessary to ensure the proper functioning of these systems. The long-term durability of thermal cooling tubes is a potential challenge.

- Potential Benefits and Future Developments: Despite the challenges, thermal cooling tubes remain a promising solution for managing heat in EV batteries. As technology advances, the complexity and cost associated with these systems may decrease. This could make thermal cooling tubes more accessible to a wider range of EV manufacturers.

Conclusion

Thermal cooling tubes offer a promising solution for managing heat in EV batteries, particularly in vehicles with limited space and high performance requirements. By providing efficient and localized cooling, these tubes can help to improve battery life, performance, and safety. As EV technology continues to advance, thermal cooling tubes are likely to play an increasingly important role in the design and development of future electric vehicles.