Understanding the Battery Management System: Key to EV Industry

In the realm of modern electronics and electric vehicles, the significance of efficient and reliable battery management cannot be overstated. A Battery Management System (BMS) stands at the forefront of this technological revolution, ensuring optimal performance, safety, and longevity of battery packs. This article delves into the technical nuances of BMS, highlighting its critical role in managing battery cells in various applications.

Explore the EV Engineering: An Initiative by All India EV…

Table of content:

1) Understanding Battery Management Systems

2) Key Components and Functions of BMS

3) Advanced Algorithms and SOC Estimation

4) Safety Protocols and Fail-safes in BMS

5) BMS in Electric Vehicles and Renewable Energy Systems

6) Master and Slave BMS Configuration

7) Centralized BMS

8) Cloud-Based BMS (Cloud BMS)

9) BMS Architecture: Hardware Components

10) BMS Architecture: Software Components

11) Comprehensive Conclusion

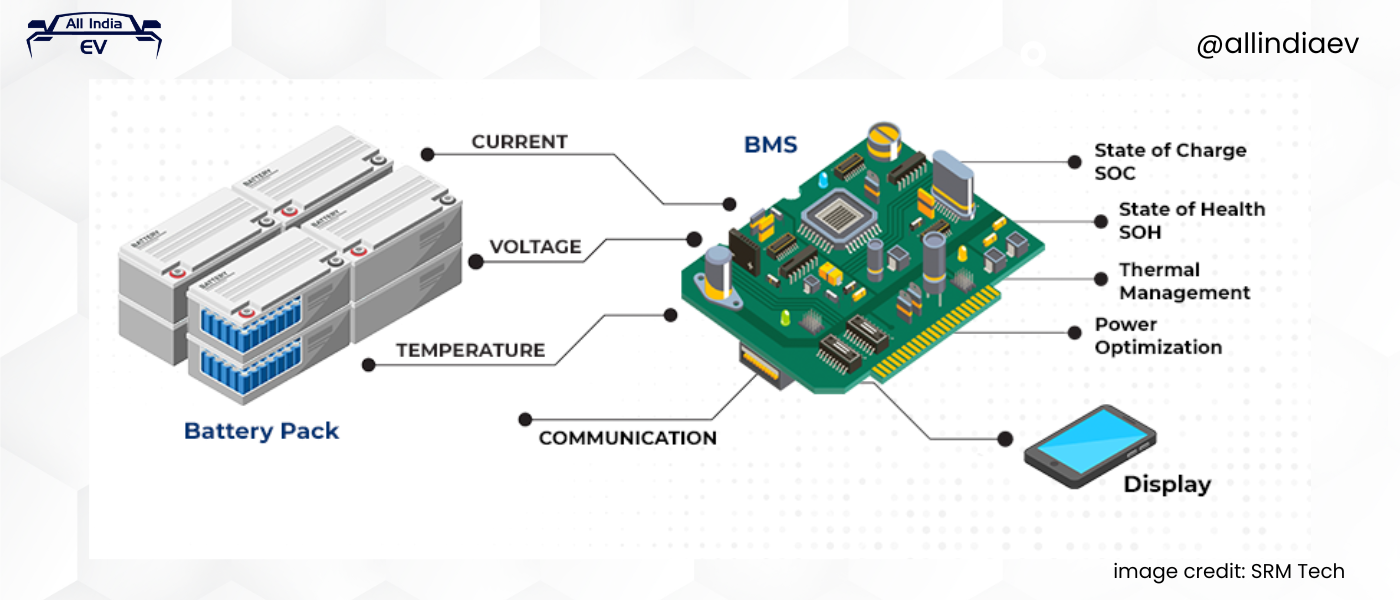

Understanding Battery Management Systems

A BMS is an electronic system that oversees and controls the charging and discharging of rechargeable batteries. The primary objective of a BMS is to ensure the battery operates within its safe operating area, which involves monitoring parameters such as voltage, current, temperature, and state of charge (SOC). This monitoring is crucial in preventing conditions like overcharging, deep discharging, and overheating, which can adversely affect battery life and performance.

Key Components and Functions

The technical architecture of a BMS includes several key components:

➡️ Sensors: These monitor vital parameters like voltage, current, and temperature at the cell level.

➡️ Control Unit: The brain of the BMS, processes data from sensors to make real-time decisions.

➡️ Balancing Mechanisms: These ensure all cells in a battery pack charge and discharge at an equal rate, maximizing efficiency and lifespan.

➡️ Communication Interface: Allows the BMS to communicate with external systems, providing crucial data for operational management.

Advanced Algorithms and SOC Estimation

One of the most sophisticated aspects of a BMS is its algorithmic prowess. Algorithms are used for SOC estimation, which is a critical factor in determining the remaining charge in a battery. Accurate SOC estimation involves complex calculations based on voltage, current, and temperature data, along with historical performance metrics.

Safety Protocols and Fail-safes

Safety is paramount in BMS design. The system incorporates multiple fail-safes and protocols to prevent hazardous scenarios like thermal runaway, short-circuiting, and cell imbalance. These safety features not only protect the battery but also ensure the safety of the end-users and the environment.

BMS in Electric Vehicles and Renewable Energy Systems

In electric vehicles (EVs), the BMS plays a pivotal role in optimizing battery performance, range, and longevity. Similarly, in renewable energy systems, such as solar power setups, BMSs are crucial for efficient energy storage and management.

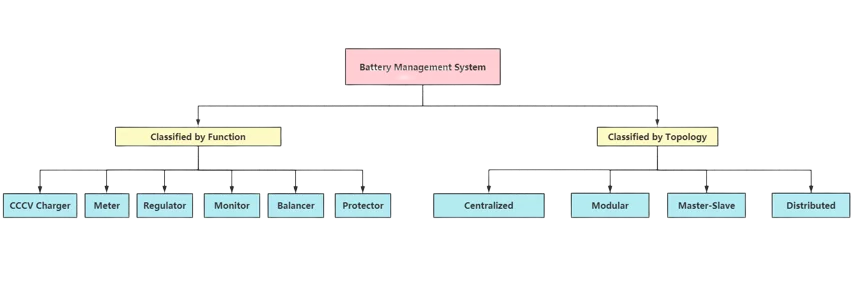

Expanding the Horizons of BMS: Master-Slave, Centralized, and Cloud-Based Systems

Master and Slave BMS Configuration

In complex battery systems, particularly those with a large number of cells, a Master and Slave configuration is often employed. This setup involves multiple BMS units where one acts as the ‘Master’ and the others as ‘Slaves’.

Master BMS: This unit is responsible for high-level functions, including communication with external systems, overall system monitoring, and decision-making based on the data collected from Slave units.

Slave BMS: Each Slave unit is dedicated to monitoring and managing a subset of the battery pack. They report to the Master BMS, providing detailed cell-level data.

This hierarchical structure allows for efficient management of large battery systems, as seen in industrial applications and large electric vehicles, by distributing the monitoring workload and enhancing system reliability.

Centralized BMS

A Centralized BMS, in contrast, involves a single control unit managing the entire battery system. This unit is responsible for all tasks, including cell monitoring, data processing, balancing, and communication. The advantages of a centralized system include:

➡️ Simplicity: Easier to design and implement, as it involves a single BMS unit.

➡️ Cost-Effectiveness: Generally more affordable due to fewer components.

➡️ Direct Control: Offers direct and comprehensive control over the entire battery system.

However, it may not be as scalable as the Master-Slave configuration, especially for very large battery systems.

Cloud-Based BMS (Cloud BMS)

The advent of cloud computing has introduced Cloud BMS, a revolutionary approach where some functionalities of the BMS are managed through cloud-based software. Key features include:

➡️ Remote Monitoring and Management: Allows for the monitoring and control of battery systems from remote locations.

➡️ Data Analytics: Utilizes cloud computing for advanced data analysis, predictive maintenance, and optimization strategies.

➡️ Scalability and Flexibility: Easily scalable, accommodating various battery system sizes and configurations.

Cloud BMS is particularly beneficial for distributed energy storage systems and electric vehicle fleets, where centralized monitoring and management can significantly enhance operational efficiency.

Delving Deeper into BMS Architecture: Hardware and Software Components

Hardware Components of BMS

The hardware of a Battery Management System forms the physical backbone of its operation. Key hardware components include:

🔸 Cell Voltage Monitoring Circuits: These circuits are crucial for measuring the voltage of individual cells or cell groups, ensuring they remain within safe limits.

🔸 Current Sensors: These sensors measure the charge and discharge currents, providing data essential for calculating the state of charge (SOC) and state of health (SOH).

🔸 Temperature Sensors: Placed at strategic points, these sensors monitor the temperature of the battery cells, preventing overheating and thermal runaway.

🔸 Balancing Hardware: Active or passive balancing circuits redistribute charge among cells to ensure uniformity, extending the battery’s lifespan.

🔸 Power Electronics: This includes components like DC-DC converters and power transistors, which manage the power flow to and from the battery.

🔸 Protection Circuitry: These circuits safeguard against over-voltage, under-voltage, over-current, and short-circuit conditions.

🔸 Communication Interfaces: Hardware interfaces (like CAN, UART, etc.) enable the BMS to communicate with external control systems.

Software Components of BMS

The software in a BMS is equally critical, providing intelligence and control capabilities. Key software components include:

🔸 Cell Management Algorithms: These algorithms manage cell balancing, charge control, and discharge limits, ensuring optimal battery performance.

🔸 SOC and SOH Estimation Algorithms: Software algorithms calculate the state of charge and health of the battery, using inputs from hardware sensors.

🔸 Thermal Management Software: This software controls the cooling or heating systems based on temperature data to maintain optimal operating conditions.

🔸 Data Logging and Analysis: The BMS software logs data for analysis, which is crucial for predictive maintenance and performance optimization.

🔸 Safety Protocols: Software-level safety checks and protocols complement the hardware safety mechanisms, ensuring a comprehensive safety net.

🔸 User Interface Software: This component allows users to interact with the BMS, providing insights into battery performance and status.

🔸 Firmware and Update Management: Ensures the BMS software can be updated for improvements and adaptation to new technologies.

Comprehensive Conclusion: The Pinnacle of Battery Management System Innovation

As we have explored, the Battery Management System (BMS) stands as a critical component in the realm of modern battery technology, playing a pivotal role in ensuring the efficiency, safety, and longevity of battery systems. From the intricate hardware that monitors and controls each cell, to the sophisticated software algorithms that provide intelligence and adaptability, the BMS is a marvel of engineering that meets the demanding requirements of a wide range of applications.

The evolution of BMS into various configurations such as Master-Slave, Centralized, and Cloud-Based systems reflects the diverse and growing needs of battery applications. Each configuration offers unique advantages, catering to specific requirements from large-scale industrial batteries to distributed energy storage systems and electric vehicles. This adaptability underscores the importance of BMS in the efficient utilization of battery energy storage.

Moreover, the architecture of a BMS, encompassing both its hardware and software components, forms the backbone of its operation. The synergy between the physical monitoring and control mechanisms provided by the hardware, and the intelligence, adaptability, and user interaction capabilities offered by the software, is what makes modern BMSs so effective and reliable.

In conclusion, the Battery Management System is not just a component; it is a testament to the advancements in battery technology and electronic engineering. As we continue to push the boundaries of what is possible with battery storage, the innovation in BMS configurations and architecture will play a crucial role in harnessing the full potential of these systems. The future of energy storage and management is bright, and BMS stands at its forefront, ensuring that we can safely, efficiently, and sustainably tap into this potential.

Some Research Papers that you can follow to understand the Battery Management System in better way:

Battery Management System in Electric Vehicle | IEEE Conference Publication | IEEE Xplore

Review of Battery Management Systems | IEEE Conference Publication | IEEE Xplore

Research on Li-ion Battery Management System | IEEE Conference Publication | IEEE Xplore