Atomic-Scale Ni Catalyst in Graphene Boosts Li–O₂ Batteries with Higher Capacity, Stability, and Safety for Next-Gen Energy Storage

In a major scientific development that could accelerate the future of electric mobility, a team of international researchers has created a dual-function catalyst that addresses two of the most persistent roadblocks in lithium–oxygen (Li–O₂) battery technology: sluggish cathode reactions and unstable lithium metal anodes.

The study, jointly conducted by researchers at Harbin Institute of Technology (Shenzhen) and Johannes Gutenberg University Mainz, and published in eScience (June 2025), introduces an atomic-scale nickel-based catalyst that simultaneously improves energy efficiency, battery stability, and overall performance.

Why It Matters for EVs

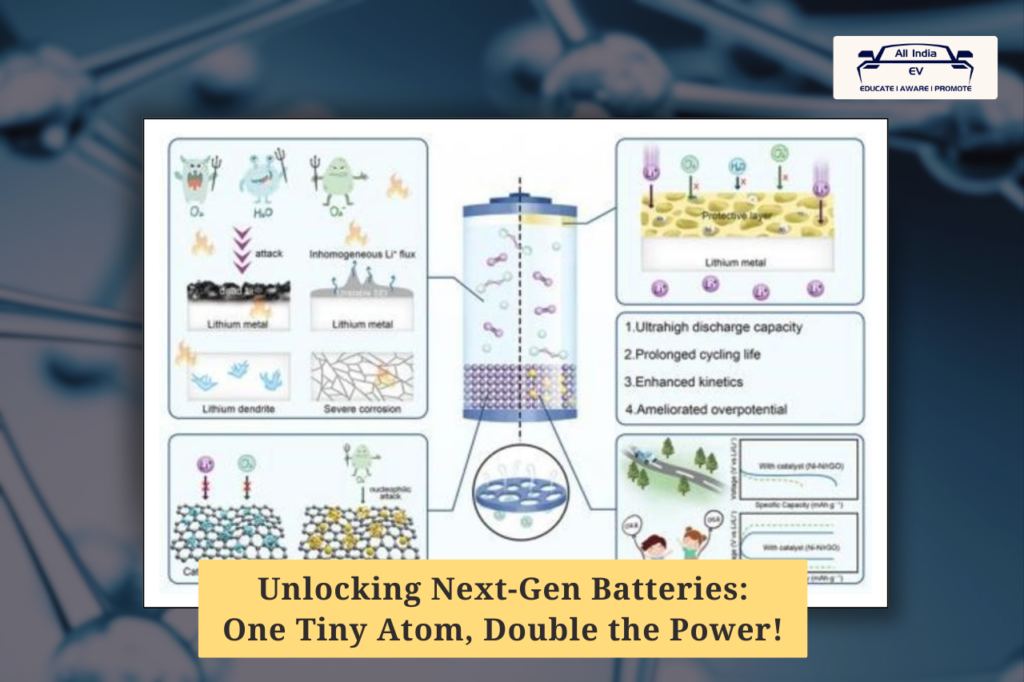

Li–O₂ batteries have long been seen as a promising next-generation solution for electric vehicles (EVs), thanks to their theoretical energy density—over 10 times that of today’s lithium-ion batteries. But practical use has been hampered by two persistent issues:

- Poor oxygen reaction kinetics at the cathode

- Dangerous lithium dendrite formation at the anode

These issues result in rapid capacity fade, voltage instability, and short battery life—factors that make them unsuitable for EV deployment, until now.

One Catalyst, Two Solutions

The research team developed a novel material called Ni–N/rGO, composed of atomically dispersed nickel sites anchored on nitrogen-doped reduced graphene oxide. This material performs a dual role:

- At the cathode – It catalyzes both oxygen reduction and evolution reactions (ORR/OER) efficiently, enabling high discharge capacity (over 16,000 mAh g⁻¹) and reduced overpotential (as low as 1.08 V).

- At the anode – It acts as a protective coating, preventing lithium dendrite growth, corrosion, and premature degradation. This extended cycle life up to 300 high-current cycles, a major leap in Li–O₂ battery performance.

Advanced testing methods including Density Functional Theory (DFT) simulations, microscopy, and XPS analysis confirmed that the catalyst promotes smooth lithium-ion movement, minimizes side reactions, and enhances long-term stability.

A Step Toward Commercial-Ready EV Batteries

“This work is significant because it solves two long-standing problems in lithium–oxygen batteries using a single material,” said Dr. Deping Li, senior author of the study. “By designing atomically dispersed nickel catalysts that simultaneously enhance cathode reaction kinetics and stabilize the lithium anode, we’ve shown a clear path toward practical, high-performance Li–O₂ systems.”

The research offers a scalable path to developing durable, high-capacity, and safer EV batteries that can operate over extended lifespans without excessive cost or complexity.

What’s Next?

While commercial deployment of Li–O₂ batteries still faces challenges related to cost, scalability, and system integration, this breakthrough could drastically reduce the technology gap. The dual-function Ni–N/rGO catalyst provides a template for future battery design, integrating atomic-level material engineering with real-world performance metrics.

Future research will focus on refining synthesis methods and exploring compatibility with other energy storage systems—including grid-scale batteries and portable electronics.